Condition Assessment Report

Sanitary Sewer Systems

Prepared for Burbank Sanitary District

Date: July 14, 2014

Submitted by: Richard K. Tanaka, District Manager

BURBANK SANITARY DISTRICT

CCTV VIDEO REVIEW AND

MANHOLE CONDITION ASSESSMENT

TABLE OF CONTENTS

1.1 Overview 1

2.0 CONDITION ASSESSMENT ACTIVITIES 2

2.1 Field Investigation Approach 2

2.2 Procedure for Condition Assessment Activities 2

3.0 ASSESSMENT STANDARD FOR GRAVITY SEWER SYSTEM 3

3.1 Pipeline Assessment and Certification Program (PACP) 3

3.2 Lateral Assessment and Certification Program (LACP) 4

3.4 Manhole Inspections 4

3.4 CCTV Inspections 5

3.5 Prompt Repair 6

3.6 Pipe Inspections 7

3.7 Visual Inspections 8

3.8 INSPECTION RESULTS 9

3.8.1 Pipe Condition 9

3.8.2 Manhole Condition 9

3.9 DISCUSSION RESULTS 10

3.9.1 Pipe Conditions Group into Each Street Block Area 10

3.9.1.1 Bailey Avenue 10

3.9.1.2 Cecil Avenue 11

3.9.1.3 Topeka Avenue 13

3.9.1.4 Cleveland Avenue 14

3.9.1.5 Brooklyn Avenue 15

3.9.1.6 Boston Avenue 17

3.9.1.7 Wabash Avenue 18

3.9.1.8 Bascom Avenue 19

3.9.1.9 Laswell Avenue 20

3.9.2.0 Vaughn Avenue 22

3.9.2.1 Arleta Avenue 23

3.9.2.2 Raymond Avenue 25

3.9.2.3 Irving Avenue 26

3.9.2.4 Leland Avenue 28

3.9.2.5 Ruthland Avenue 31

3.9.2.6 Clifton Avenu 34

3.9.2.7 Leigh Avenue 36

3.9.2.8 Richmond Avenue 37

3.9.2.9 Easement between Bascom ‐ Laswell Avenue 39

3.9.3.0 Easement between Laswell – Arleta Avenue 41

3.9.3.1 Easement between Arleta – Raymond Avenue 43

3.9.3.2 Easement between Raymond ‐ Irving Avenue 46

3.9.3.3 Easement between Irving ‐ Leland Avenue 48

3.9.3.4 Forest Avenue 50

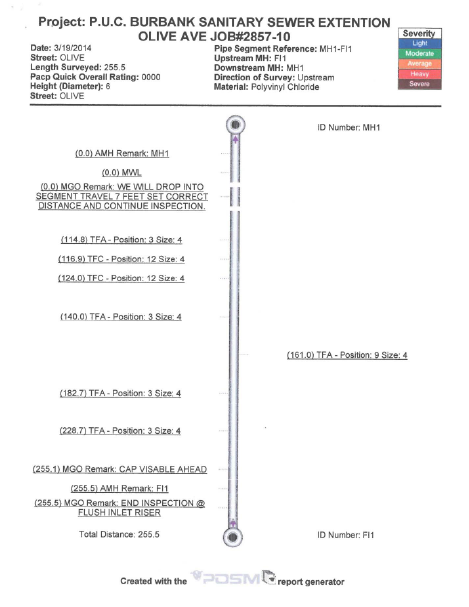

3.9.3.5 Olive Street 51

3.9.3.6 Scott Street 51

3.9.3.7 Capacity Assessment Results 56

TABLES

Table 3.1: Structural and O&M Defects Grading Table 3

Table 3.2: General Guidelines Regarding Deterioration Rates 4

Table 1‐1: Pipe Condition Determination Criteria 8

Table 1‐2: Condition of Manholes 9

Table 1‐3: Bailey Avenue Sanitary Sewer 10

Table 1‐4 Cecil Street Sanitary Sewer 11

Table 1‐5: Topeka Avenue Sanitary Sewer 13

Table 1‐6: Cleveland Avenue Sanitary Sewer….. 14

Table 1‐7: Brooklyn Avenue Sanitary Sewer 16

Table 1‐8: Boston Avenue Sanitary Sewer 17

Table 1‐9: Wabash Avenue Sanitary Sewer 19

Table 1‐10: Bascom Avenue Sanitary Sewer 20

Table 1‐11: : Laswell Avenue Sanitary Sewer 21

Table 1‐12: Vaughn Avenue Sanitary Sewer 22

Table 1‐13: Arleta Avenue Sanitary Sewer 23

Table 1‐14: Raymond Avenue Sanitary Sewer 25

Table 1‐15: Irving Avenue Sanitary Sewer 26

Table 1‐16: Leland Avenue Sanitary Sewer 28

Table 1‐17: Ruthland Avenue Sanitary Sewer 32

Table 1‐18: Clifton Avenue Sanitary Sewer 34

Table 1‐19: Leigh Avenue Sanitary Sewer 36

Table 1‐20: Richmond Avenue Sanitary Sewer 38

Table 1‐21: Easement between Bascom‐Laswell Avenue Sanitary Sewer 39

Table 1‐22: Easement between Laswell‐Arleta Avenue Sanitary Sewer 41

Table 1‐23: Easement between Arleta‐Raymond Avenue Sanitary Sewer 43

Table 1‐24: : Easement between Raymond‐Irving Avenue Sanitary Sewer. 47

Table 1‐25: Easement between Irving‐Leland Avenue Sanitary Sewe 48

Table 1‐26: : Forest Avenue Sanitary Sewer 50

Table 1‐27: Olive Avenue Sanitary Sewer 51

Table 1‐28: Scott Avenue Sanitary Sewer 52

FIGURES

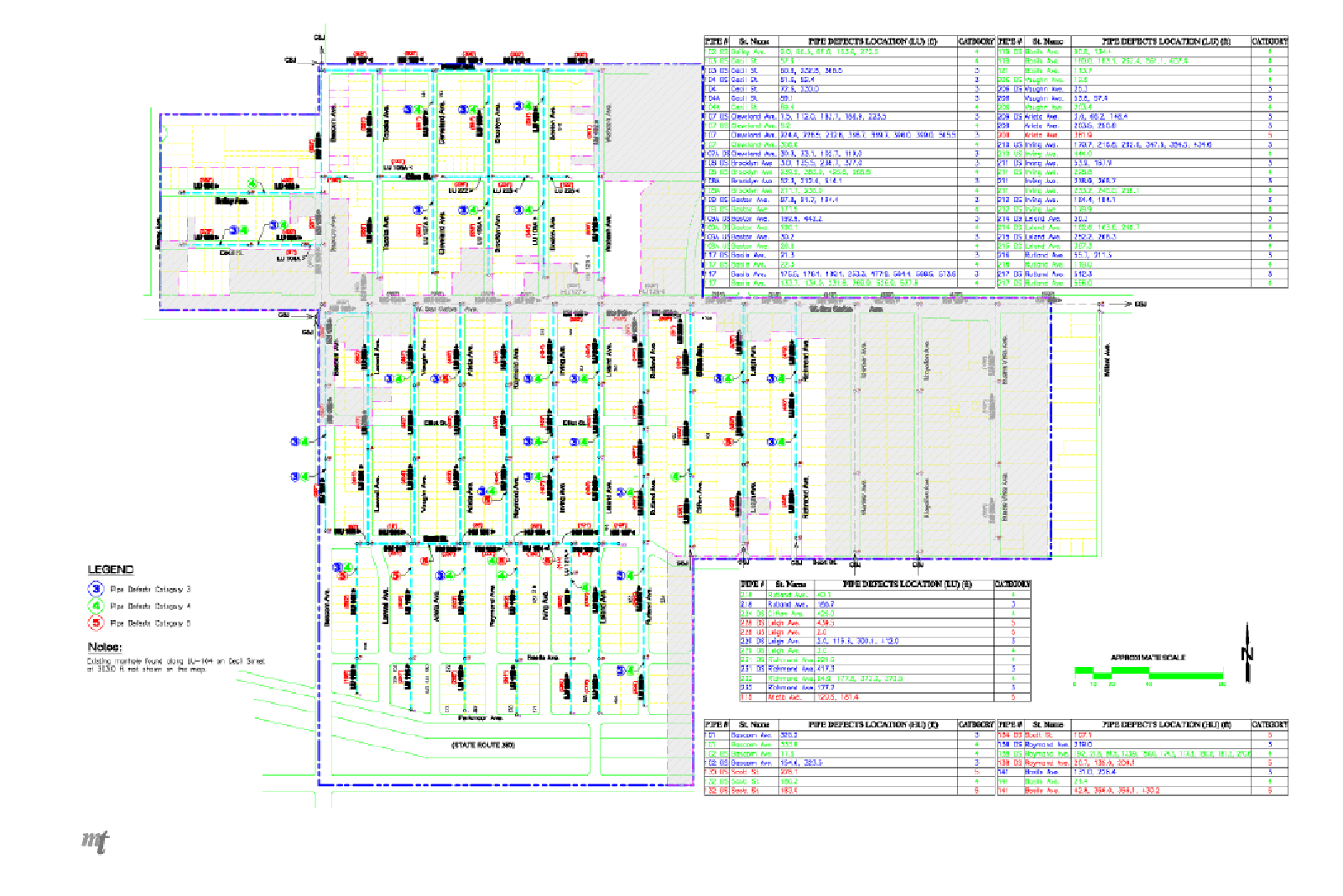

Figure 1‐1 Burbank Sanitary District Defects Maps 58

APPENDIX A: PIPE ISSUE SUMMARY TABLES

Table A‐2: Sanitary Sewer System Pipe Containing Grease 60

Table A‐3: Sanitary Sewer System Pipe Containing fine and Medium Roots 61

Table A‐4: Sanitary Sewer System Pipe Sags 63

Table A‐5: Sanitary Sewer System Other Pipe Issues 65

APPENDIX B: MANHOLE SEWER CONDITIONS

Table B‐1: Sanitary Sewer Manhole 67

APPEXDIX C: PIPE INSPECTION LOGS

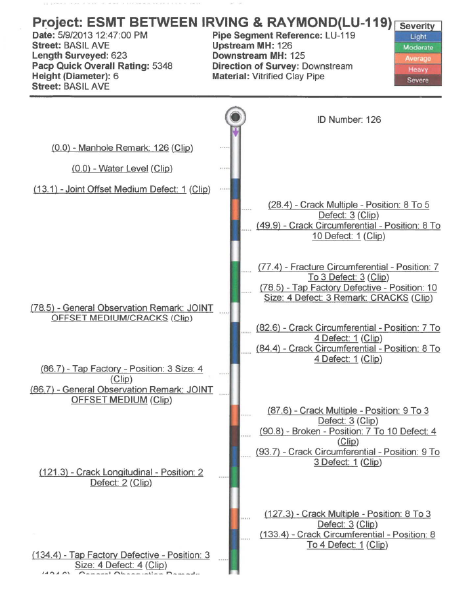

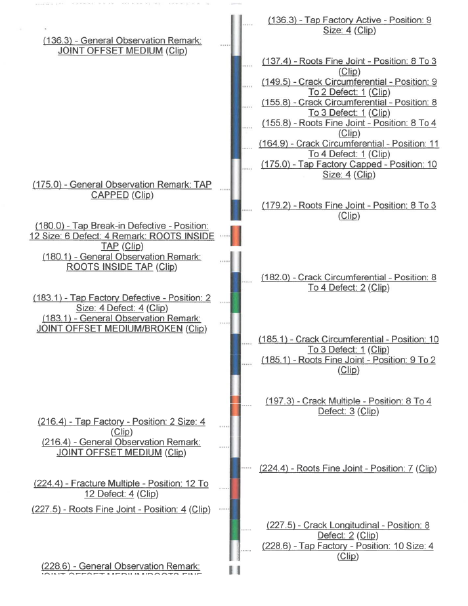

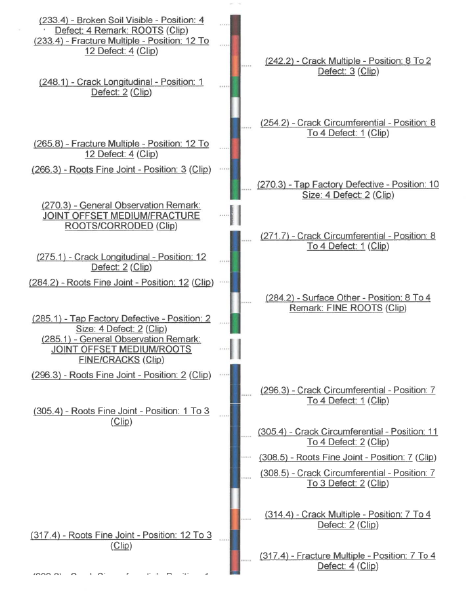

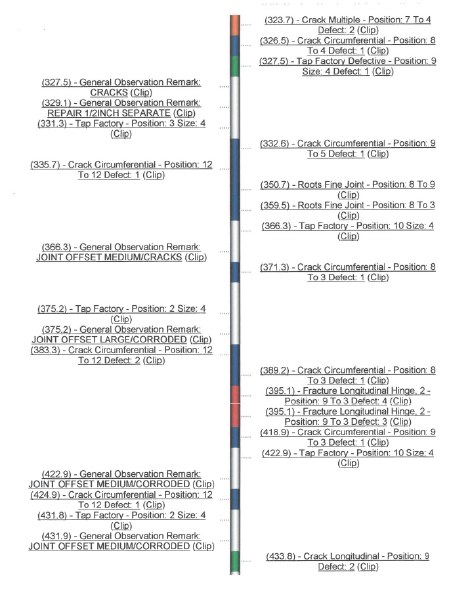

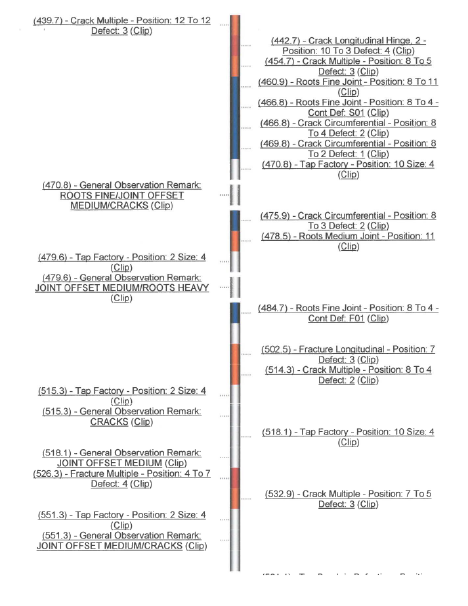

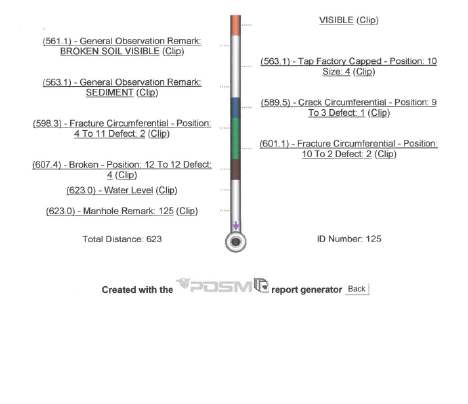

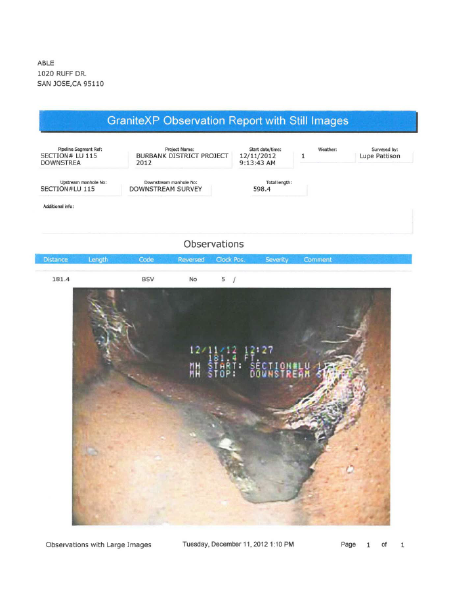

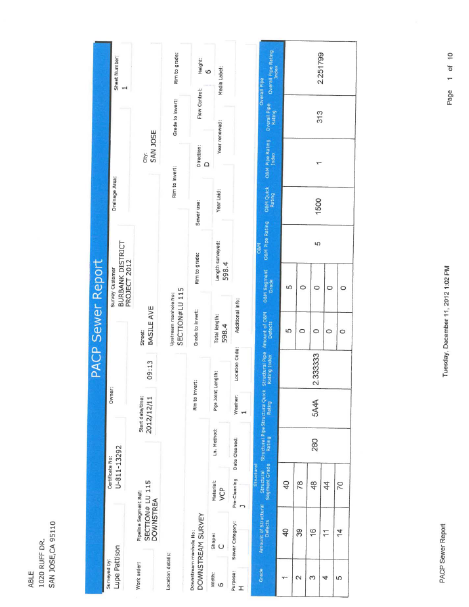

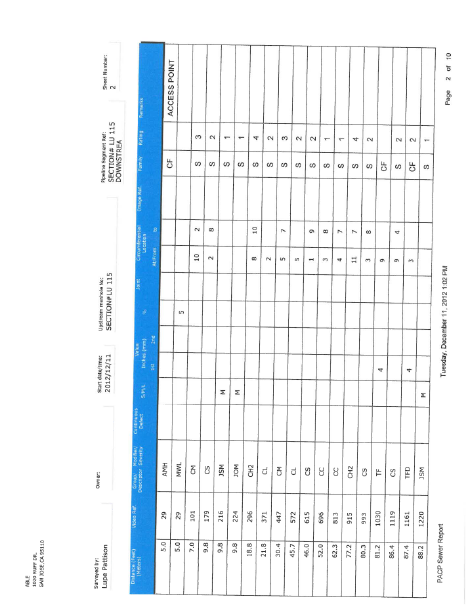

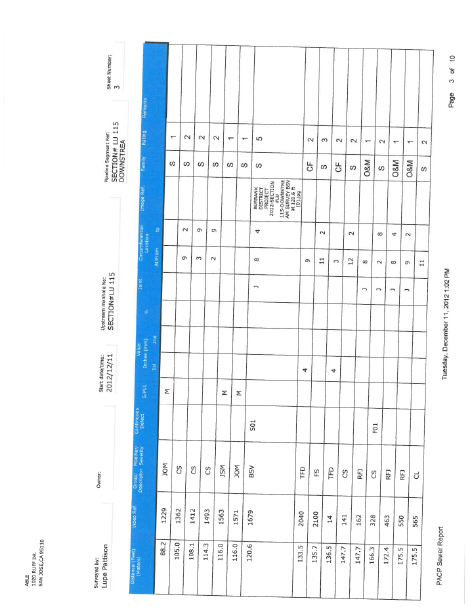

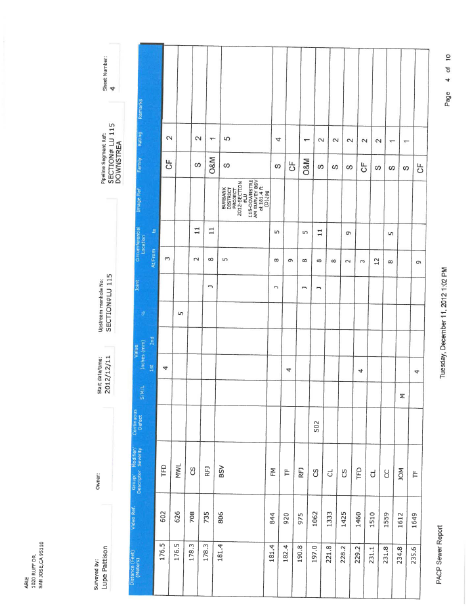

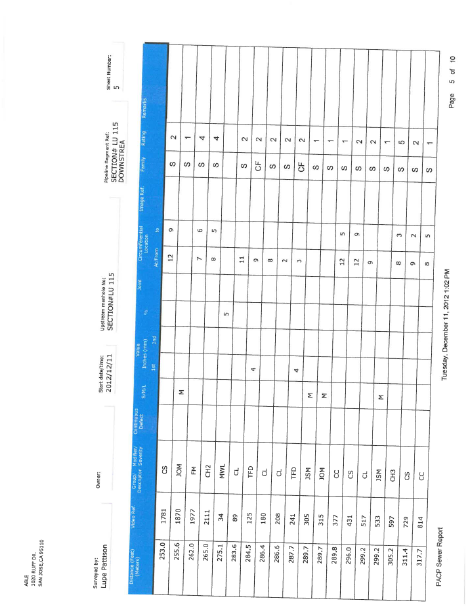

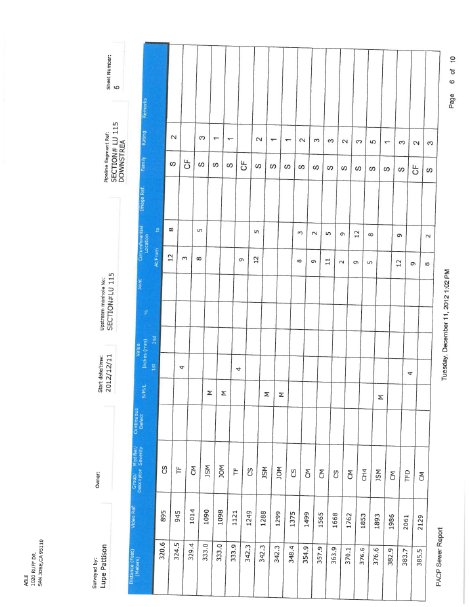

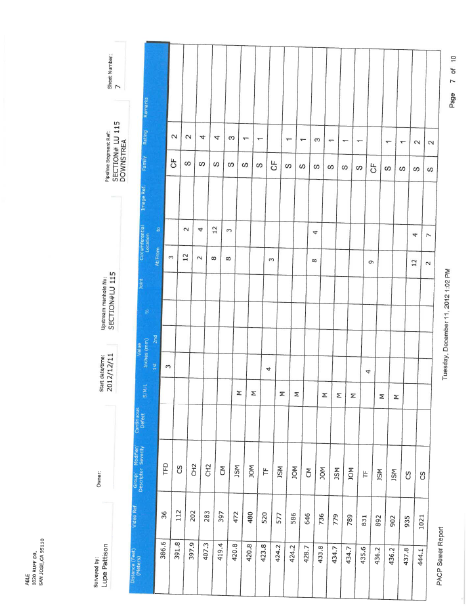

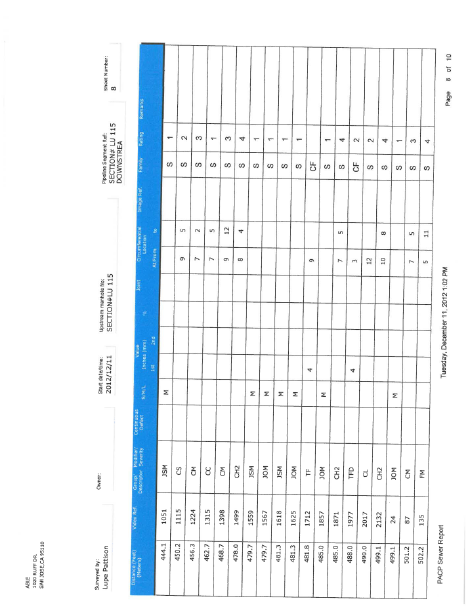

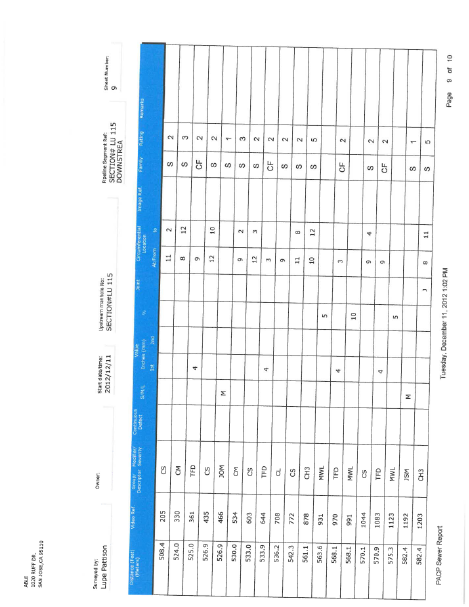

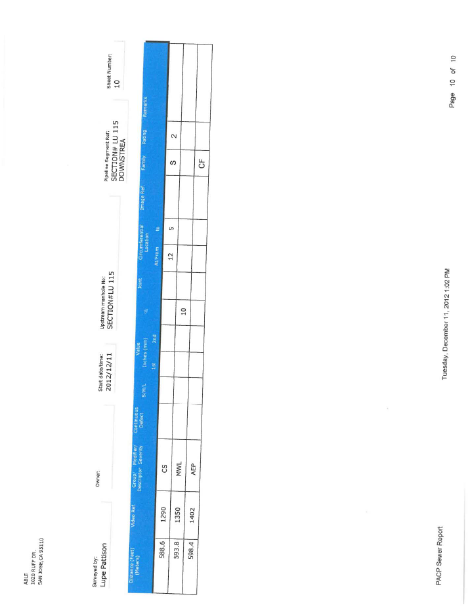

Figure C‐1: Simple Report of LU‐119 by Presidio System 71

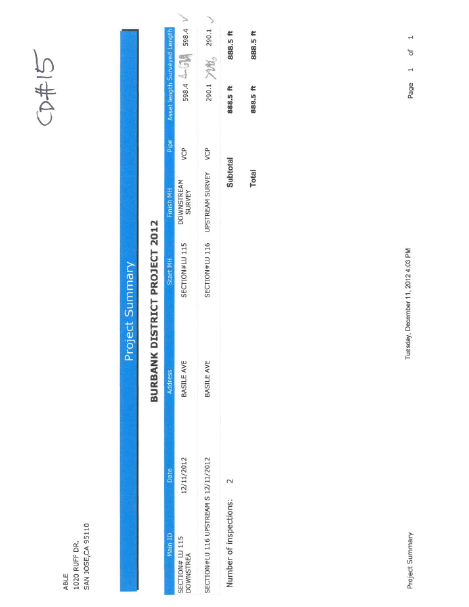

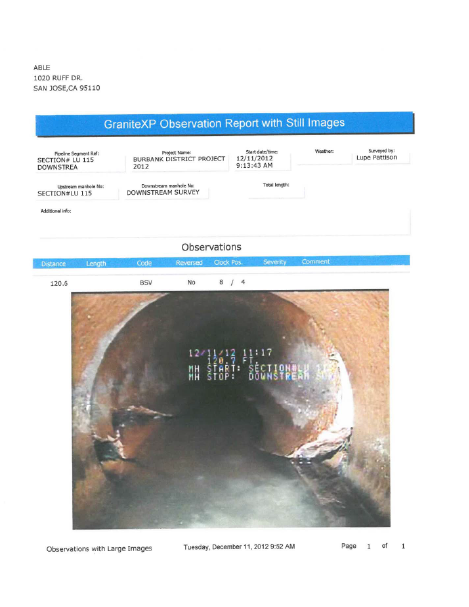

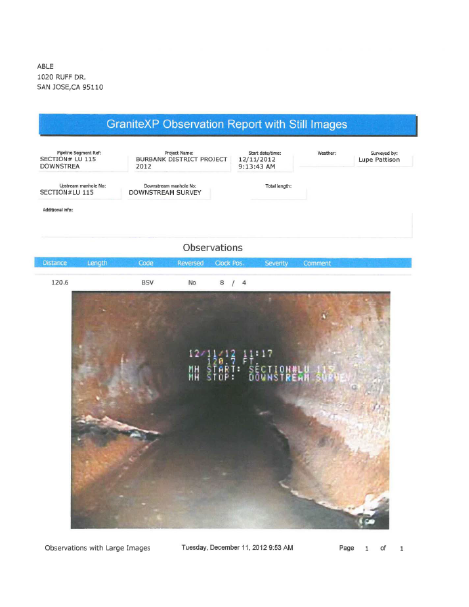

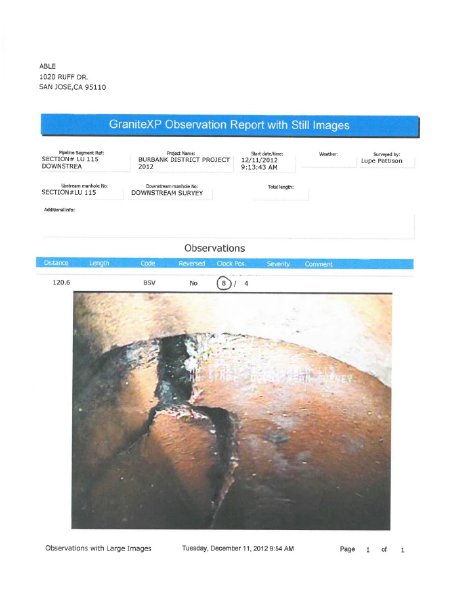

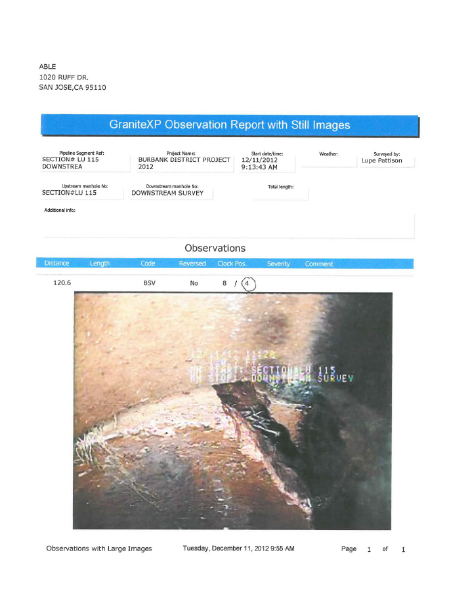

Figure C‐2: Simple Report of LU‐115 by ABLE Underground Construction 77

Figure C‐3: Simple Report of LU‐222 by Pacific Underground Construction 93

APPEXDIX D: SUMMARY AND RECOMMENDATION

Table D‐1: Sewer Main Segments Recommended For Rehabilitation/ Replacement 95

Table D‐2: BSD, 5‐Year Capital Improvements Program (2014‐2019) 98

Table D‐3: BSD, 5‐Year Capital Improvements Program (2019‐2024) 100

BURBANK SANITARY DISTRICT

1.0 EXECUTIVE SUMMARY

1.1 Overview

Mark Thomas and Company, Inc. as the District Manager‐Engineer, has completed the Condition Assessment for the Burbank Sanitary District. This report consist a condition assessment of Burbank Sanitary District Sewer System and an implementation schedule based on field observations, data developed and collected from close circuit television (CCTV Contractors) ABLE Underground construction and Presidio System Inc. ABLE Underground Contractor and Presidio System Inc. were retained by Burbank Sanitary District (BSD) to perform a CCTV of approximately twenty nine thousand eight hundred and eighty one (29,881) lineal feet of sanitary sewer mains, thirteen (13) flush inlet and sixty (60) manholes that are part of the trunk sewer which serves the Burbank Sanitary District. ABLE Underground Construction and Presidio System were tasked to review CCTV video tapes of the sanitary sewer mainline at each block of the street. The sanitary sewer mainlines as shown in Figure 1‐1.

There were two primary tasks: (1) manhole condition assessment and (2) CCTV to determine pipeline condition. BSD’s staffs conducted topside condition assessments of 59 manholes and 8 flush inlets (1 MH and 5 FI were inaccessible). The condition assessments did not involve a confined space entry. Topside assessment of the MH and FI was performed concurrent with the CCTV task. The topside assessments were performed in December 2012 and May 2013.

Burbank Sanitary District (BSD) had conducted condition assessment of assets within its sanitary sewer for the purpose of developing future capital improvement needs and prioritizing the improvements that present a highest “material risk of failure”. For the purposes of this document, “failure” means any condition resulting in a sanitary sewer overflow, pipe leakage, or interruption of service to BSD’s customers, due to a physical condition defect in the system. The goal of the Condition Assessment Plan is to develop a working plan and schedule for inspecting, assessing, and prioritizing BSD’s sanitary sewer system assets, and to develop a recommended Capital Improvement Program (C.I.P) for implementing wastewater collection system projects to meet immediate needs as well as to continue funding the on‐going condition assessment and rehabilitation programs. The Condition Assessment Plan will provide standard methods for evaluating the physical condition of BSD’s sanitary sewer assets in order to identify assets that present a “material risk of failure”

The condition of the sanitary sewer manholes and sanitary sewer mains was included in the assessment. CCTV results concluded that the sanitary sewer system pipes contained many blockages due to debris, grease, and roots, with several pipe sags, cracks, break and deformation. Much of the sanitary sewer system is composed of vitrified clay pipe, a material not used in modern sanitary sewer construction. The inspection results are summarized in Table A‐1.

| Condition | Sanitary Sewer Pipe | Sanitary Sewer Manholes | |

|---|---|---|---|

| 1 | Excellent | 818 feet (2.64%) | (0%) |

| 2 | Good | 3742 feet (12.52%) | 9 (15.25%) |

| 3 | Fair | 12,423 feet (41.57%) | 50 (84.75%) |

| 4 | Poor | 12,898 feet (43.16%) | (0%) |

| 5 | Total | 29,881 feet | 59 |

In summary, manholes are in fair to good conditions. However, over 40% of the sewer mains are in poor condition and will need to be rehabilitated

The estimated cost for rehabilitation is $2,420,000 which is for pipes in “poor and fair” conditions. Based on above table, the division between poor and fair is about 50‐50 split. For implementation, refer to Section 3.9.3.7, “Condition Assessment Results and Recommendation”.

2.0 CONDITION ASSESSMENT ACTIVITIES

2.1 Field Investigation Approach

The object of the Condition Assessment Activities is to provide an appropriate level of system information to support sound rehabilitation and or replacement decisions for BDS’s sanitary sewer system. The objectives of a standardize field investigation approach is to evaluate sewer assets without expending unnecessary time and resources, and executed investigation and or rehabilitation efforts are utilized where appropriate.

2.2 Procedure for Condition Assessment Activities

The condition of assets in BSD’s sanitary sewer system was assessed using data collection methods. Uniform assessment was conducted to aid in the evaluation of data and provided a common basis for assessing rehabilitation needs. Databases system was used by BSD to store and manage asset condition data collected during the assessment activities. Sanitary sewer system was inspected for structural integrity and maintenance issues. These assessment activities included manhole visual inspections, pipeline inspection using close circuit television (CCTV).

3.0 ASSESSMENT STANDARDS FOR GRAVITY SEWER SYSTEM

The National Association of Sewer Service Companies (NASSCO), along with the assistance of the Water Research Centre (WRC), has developed a national certification program to establish a viable solution to standardize the identification, categorization, evaluation, and prioritization of sanitary sewer or storm sewer infrastructure through CCTV investigations. This standardized certification program was used to ensure consistent record‐keeping when compiling CCTV reports into a common database which can then be used for operation and maintenance (O&M) activities as well as pipe rehabilitation and replacement.

NASCCO PACP standards was used to conduct CCTV investigations and document findings. The PACP defect descriptions are organized into the following general categories:

- Structural Defect Coding: This group includes the type of defects where the pipe is considered to be damaged ranging from a minor case defect to a more severe case, depicted as pipe failure. The Structural Defect Coding group includes defects described as: cracks, fractures, broken pipe, holes, deformities, collapsed pipe, joint defects, surface damage defects, weld failures, point repair codes, brickwork defects, and lining failures.

- Operation and Maintenance Coding: This group includes the various codes that involve the spectrum of defects that may impede the operation and maintenance of the sewer piping system. The Operation and Maintenance Coding group includes defects comprised of roots, infiltration, deposits and encrustations, obstacles/obstructions, and vermin.

- Construction Features Coding: This group includes the various codes associated with the typical construction of the sewer piping system. The Construction Features Coding group includes taps, intruding seal material, pipe alignment codes, and access points.

- Miscellaneous Features Coding: This group includes observation codes such as water levels (detection of sags), pipe material changes, and dye testing notes.

PACP Condition Grading System

The tables below describe the grading system for structural and O&M defects, and general guidelines regarding deterioration rates. Each defect can be scored with a grade ranging from 1 to 5, where a grade 5 has the most potential for pipe failure.

Table 3.1 Strcutural and O&M Defects Grading Table

| Grade | Grade Description | Grade Definition | |

|---|---|---|---|

| 1 | 5 | Immediate Attention | Defects requiring immediate attention |

| 2 | 4 | Poor | Severe defects that will become Grade 5 defects within the foreseeable future |

| 3 | 3 | Fair | Moderate defects that will continue to deteriorate |

| 4 | 2 | Good | Defects that have not begun to deteriorate |

| 5 | 1 | Excellent | Minor defects |

Table 3.2 General Guidelines Regarding Deterioration Rates

| Grade | Grade Definition | |

|---|---|---|

| 1 | 5 | Pipe has failed or will likely fail within the next 5 years |

| 2 | 4 | Pipe will probably fail in 5 to 10 years |

| 3 | 3 | Pipe may fail in 10 to 20 years |

| 4 | 2 | Pipe unlikely to fail for at least 20 years |

| 5 | 1 | Failure unlikely in the foreseeable future |

Lateral Assessment was not included in BSD’s Condition Assessment Report because majority of the sewer laterals connection from individual customers tying into the BSD gravity sewer main system do not have an access point such as (property line cleanout).

3.3 Manhole Inspections.

Sanitary sewer manhole inspections are an important component of the gravity sewer system assessment due to the susceptibility of manholes to structural defects and/or Inflow/Infiltration which may contribute to SSOs. Manhole inspection not only provides valuable information on the physical condition of the manholes, but also an opportunity to observe pipe diameters, inverts, and surcharging within mainline gravity sewers. Manhole inspection was completed by the certified personnel performing the manhole inspection. Prior to conducting inspections of manhole components, a non‐entry (topside) manhole inspection was conducted to determine the overall condition of the manhole as viewed from the ground surface. The surrounding area was observed and noted if manholes or adjacent cleanouts are located in areas that are conducive to flooding or ponding that allows water to enter the sanitary sewer system. The following documentation was collected at each manhole.

- Photographs the above ground location of the manhole

- Photographs the interior of the manhole looking down at the manhole invert and looking into the incoming and outgoing pipelines

- Potential issues

- Significant defects which are observed during the manhole assessment

- Photographs will be stored in electronic format.

3.4 CCTV Pipe Inspections

Close Circuit Television (CCTV) video inspection had was performed to assess the condition

BSD’s sanitary sewer main pipes to confirm the location and magnitude of structural defects,

points of inflow and infiltration, lateral locations, undocumented/illegal connections, existing

pipe lining, and blockages within the system.

CCTV inspections was conducted in accordance with NASSCO PACP standards. Personnel performing CCTV inspections were PACP‐certified and completed all inspections using standard PACP codes for all defects and observations during the inspection. CCTV data will be managed in a PACP‐compliant software product. CCTV inspections was recorded in color using a pan‐ and‐tilt, radial‐viewing inspection to allow video/image to be sufficiently clear to easily observe sewer line defects and features including the location of service laterals.

Prior to conducting CCTV inspections, the gravity sewer pipes and manholes was cleaned per District’s requirement. Cleaning consisted of normal hydraulic jet cleaning to facilitate the internal CCTV inspection. CCTV inspections was not performed in sewer lines with flow depths that do not allow the CCTV equipment to freely pass through the gravity sewer system at the time of inspection.

Gravity main inspections was identified and tracked by recording the upstream and downstream manholes using BSD’s manhole identifiers. CCTV inspections was conducted from an upstream manhole to a downstream manhole in the direction of gravity sewer flow to minimize splashing and to allow a smoother pass of the CCTV equipment. The entire length of sewer line undergoing inspection was recorded in this direction unless site conditions make it necessary to stop the CCTV inspection, in which case a reverse‐flow set‐up was attempted. During the CCTV inspection, the CCTV camera was temporarily stopped at each observed defect or service lateral in order to obtain a clear still picture and video image, as well as a verbal description of the observation.

The camera inspections of pipes commenced on December 10, 2012 and were completed on May 30, 2013 by Presidio System, Inc. Livermore, California and ABLE Underground Construction, San Jose, California. Also on March 19, 2014 Pacific Underground Construction conducted a CCTV for additional three segments of pipe constructed more recently with modern PVC sewer pipes on Olive Street which run between Cleveland Avenue and Wabash Avenue. CCTV data was collected both by District staffs and with CCTV Contractors. CCTV data was collected with fully equipped CCTV vehicles. The CCTV operators coded defects either by structural or maintenance defects. Each defect code was assigned a grade of 1 to 5, with 1 being the least severe and 5 being the most severe defect. These grades only consider the internal pipe conditions obtained from the televised inspection. District staffs reviewed CCTV videos tape of the sewer main at each block of the street, including the sewer main located in the easement areas. District staffs assessed the condition of the pipeline using the National Association of Sewer Service Companies (NASSCO) Pipeline Assessment and Certification Program (PACP) to provide standardization and consistency in the evaluation of sewer pipe condition. BSD’s staffs conducted condition assessments of assets within its sanitary sewer system for the purpose of locating conditions that present a material risk of failure. “Failures” means any condition resulting in a sanitary sewer overflow, pipe leakage, or interruption of service to BSD‘s customer, due to physical condition defect in the system.

A pan‐and‐tilt color camera was used to conduct the camera inspections, allowing the operator to rotate, raise and lower the camera head to provide the optimum view of the interior of the pipes. The camera was stopped at each service connection and lateral, and rotated to allow the inspection of the interior of each connection. All video was recorded in MPEG‐1 format and stored directly on labeled DVDs/District hard‐drives. The log information for each pipe segment included street location, manhole numbers, pipe size, pipe material, line items for each comment and defect, and a schematic diagram of the manhole‐to‐manhole observations. The defects that were noted included broken pipe, cracks, offset joints, root intrusions, grease accumulation, infiltration, and pipe obstructions. The goal of the Condition Assessment is two‐ fold (1) to develop future capital improvement programs and (2) to develop a working plan and schedule for inspecting, assessing, prioritizing BSD’s sanitary sewer system assets and prompt repair.

3.5 Prompt Repairs

The Prompt Repairs concept provides a process by which critical system repairs can be made in a more timely and cost effective fashion. Prompt repair methodology employs the concept that when critical failures or deficiencies warranting prompt repair are found during condition assessment activities, actions will be taken to correct the problems by on‐call Contractors. Prompt repairs of sanitary sewer infrastructure assets are warranted when critical defects are found that meet these following criteria.

a. Pose an immediate threat to the environment.

b. Pose an imminent threat to the public health and safety

c. Create operational problems that may result in SSOs

d. Contribute substantial inflow to the system

For BSD, this approach was not implemented, unless District staff determined that the defects to be urgent and critical “in needs of rehabilitation”. Rather, the approach of developing a long term capital improvement program was the preferred approach.

3.6 Pipe Inspections

The following streets of the sanitary sewer pipe system were inspected: Pipe run along west east direction from Revey Avenue continues east to Bascom Avenue, pipe run along north south direction between W. San Carlos Avenue and Forest Avenue, and pipe run along north south direction between Scott Avenue and W. San Carlos Avenue, also pipe run along north south direction in an easement areas between Parkmoor Avenue and Scott Avenue.

Segment of pipes between Revey Avenue and Bascom Avenue

1. Bailey Avenue

2. Cecil Street

Segment of pipes between W. San Carlos and Forest Avenue

3. Forest Avenue

4. Olive Avenue

5. Scott Avenue

6. Topeka Avenue

7. Cleveland Avenue

8. Brooklyn Avenue

9. Wabash Avenue

Segment of pipes between Scott Avenue and W. San Carlos Avenue

10. Bascom Avenue

11. Laswell Avenue

12. Vaughn Avenue

13. Arleta Avenue

14. Raymond Avenue

15. Irving Avenue

16. Leland Avenue

17. Ruthland Avenue

18. Cliffton Avenue

19. Leigh Avenue

20. Richmond Avenue

Sanitary sewer main pipes in an easement areas run north south between Parkmoor Avenue and Scott Avenue.

a. Between Bascom Avenue and Laswell Avenue

b. Between Laswell Avenue and Arleta Avenue

c. Between Arleta Avenue and Raymond Avenue

d. Between Raymond Avenue and Irving Avenue

e. Between Irving Avenue and Leland Avenue

The following report is an analysis of the results of the sanitary sewer pipe inspections.

Each segment of the pipe was assigned a condition by Presidio Systems, Inc. and ABLE underground construction using the categories of “excellent,” “good,” “fair,” and “poor.” These conditions were assigned based on the presence of cracks/breaks, pipe blockages, grease, sags or fine roots. Table 1‐1 summarizes how the criteria were applied to the determination of pipe conditions based on the camera inspection data

Table 1-1: Pipe Condition Determination Criteria

| Condition Evaluation | Determination Criteri | |

|---|---|---|

| 1 | Excellent | No cracks or breaks, No pipe blockages, No grease, No Pipe Sags, No fine roots |

| 2 | Good | No cracks or breaks, May contain pipe blockages up to 5%, No grease, May contain pipe sags up to 5%, May contain fine roots |

| 3 | Fair | No cracks or breaks, May contain pipe blockages up to 30%, May contain grease up to 10%, May contain pipe sags up to 25%, May contain fine roots |

| 4 | Poor | May contain cracks or breaks, May contain pipe blockages greater than 30%, May contain grease greater than 10%, May contain pipe sags greater than 25%, May contain fine roots |

This report represents items developed based on our observations as part of this condition assessment process

3.7 Visual Inspections

The visual inspections of the manholes were conducted during the CCTV operation by the CCTV Contractors and District’s Inspector. The structural condition, amount of sediment, flow volume, flow contents, debris and odor were observed and noted for each manhole. Each manhole was then assigned an overall condition of “excellent,” “good,” “fair,” or “poor” during the visual inspection.

3.8 INSPECTION RESULTS

3.8.1 Pipe Condition

During the inspections, twenty nine thousand eight hundred and eighty one (29,881) lineal feet of sanitary sewer main pipe were inspected. During the inspections, approximately 530 feet of pipe could not be inspected due to site conditions such as inaccessible or pipe blockages. Approximately one thousand four hundred and fifty (1450) lineal feet of the inspected pipes were 10 inches, two thousand three hundred and fifty four (2,354) lineal feet of the inspected pipes were 8 inches, and the remainder of twenty six thousand seventy seven (26,077) lineal feet of the inspected pipes were 6 inches in diameter. Of the inspected pipes, approximately 95.61% (28,568 feet) were vitrified clay pipe. The remaining approximately 1,313 feet of pipe consisted of PVC and asbestos cement pipe

Approximately 818 feet of pipe (2.64%) was determined to be in excellent condition, approximately 3,896 feet (12.58%) was determined to be in good condition, approximately 13,538 feet (43.71%) was determined to be in fair condition, and approximately 12,720 feet (41.07%) was determined to be in poor condition. The diameter of the pipes did not correlate closely with the condition of the pipes.

The inspected portion of the sanitary sewer systems, which were rated “poor condition”, contained multiple breaks, multiple cracks, holes soil visible and multiple fractures. There were multiple pipe blockages including intruding roots, a pipe misalignment, pipe broken, and an intruding tap. Pipe blockages ranged from 10%‐95%. There were also several instances of fine and medium roots. While fine roots do not require immediate attention, those sections of mains will need to inspected and maintained on a regular basis. There were 37 instances of grease ranging from 5%‐10%. There were also 97 pipe segments with sagging ranging from 5%‐ 50%. There were also 5 pipe segments that contained issues causing the abandonment of the inspection of the pipe, including water and a siphon. See Appendix A for a summary of pipe issues and Appendix B for a table of all pipe conditions.

3.8.2 Manhole Condition

Fifty nine (59) existing manholes throughout the Burbank Sanitary District were inspected. These manholes were determined to be in good and fair condition. Table 1‐2, below contains a summary of how many of the inspected structures were rated in the individual categories, as well as overall condition.

Table 1-2: Condition of Manholes

| Structural Condition | - | Sediment | - | Hydraulic Condition | - | Overall Condition | - | |

|---|---|---|---|---|---|---|---|---|

| 1 | Good | 59 | None | 10 | Good | 59 | Excellent | 0 |

| 2 | Damaged Functional | Partial | 14 | Damaged Functional | 0 | Good | 9 | |

| 3 | Damaged Non‐ Functional | Substantial | 0 | Damaged Non‐ Functional | 0 | Fair | 50 | |

| 4 | Full | 0 | Blocked | 0 | Poor | |||

The individual inspection results for each manhole can be found in the Sanitary Sewer Manholes Table in Appendix B.

3.9 DISCUSSION OF RESULTS

3.9.1 Pipe Conditions Group into Each Street Block Areas

Pipes were grouped into each street block areas, as shown in Figure 1‐1. Below are summaries of the pipe conditions in each street block areas. See Appendix C for pipe inspection logs.

3.9.1.1 Bailey Avenue

Two sanitary sewer pipe segments were inspected at Bailey Avenue. They ranged in condition from poor to fair. The segment of pipe between MH201 and MH202, and between MH202 and MH2 consisted several locations of pipe in poor condition which included broken, crack and fracture circumferential, crack and fracture longitudinal, crack and fracture multiple and joint offset with a defect ranging from 2 to 5. The pipe in fair condition at the present time was, in our opinion, approaching in near future (within 3 to 5 years) to be “in poor condition” because of it contained cracks and fracture circumferential at multiple locations throughout the pipe. Also several areas of these pipe segments contained 5% grease, 5% of sags and fine roots. In summary, the average condition of the pipes in this area was fair.

Table 1-3: Bailey Avenue Sanitary Sewer

| Historic ID | - | Section ID | Description | - | - | - | - | - | |

|---|---|---|---|---|---|---|---|---|---|

| 1 | Start Location | End Location | Pipe Segment Reference | Broken, Cracks, Fracture, and Joint offset (Distance from Start) | Blockage (%) | Grease (%) | Sags (%) | Fine Roots | Condition |

| 2 | MH201 | MH202 | LU‐101 | Circumferential Crack – 171.7 Longitudinal Crack‐ 227.6, 355.6 Multiple Crack‐ 215.7, 312.8 Circumferential Fracture– 11.8 | 5 | 5 | Fair | ||

| 3 | MH202 | MH2 | LU‐102 | Broken– 9.0 Circumferential Crack‐ 3.1, 77.9, 90.2, 108.5, 111.8, 26.6, 138.9, 168.9, 14.6, 257.3, 266.4, 78.8, 287.8, 363.8 Longitudinal Crack‐ 153.8, 229.7 | 5 | 5 | Y | Poor | |

| 4 | Multiple Crack‐ 21.3, 33.6, 39.5, 84.2,132.6, 166.1, 263.4 Circumferential Fracture‐ 241.9 Longitudinal Fracture‐ 80.5 Multiple Fracture‐ 81.0, 272.5 Joint Offset‐ 391.3 | ||||||||

3.9.1.2 Cecil Street

Three sanitary sewer pipe segments were inspected at Cecil Street. They ranged in condition from poor to fair. The segment of pipe between MH203 and MH 204, MH204 and MH204A and MH 204A and MH3 consisted several locations of pipe in poor condition which contained broken, crack and fracture circumferential , crack and fracture longitudinal, crack and fracture multiple, joint offset and tap break in and tap factory defective with a defect ranging from 3 to 4. The pipe in fair condition is in similar situation as noted for Bailey Avenue. Also several areas of these pipe segments contained 5% grease and 5% sags. In summary, the average condition of the pipes in this area was fair.

Table 1-4: Cecil Street Sanitary Sewer

| Historic ID | - | Section ID | Description | - | - | - | - | - | |

|---|---|---|---|---|---|---|---|---|---|

| 1 | Start Location | End Location | Pipe Segment Reference | Broken, Cracks, Fracture, and Joint offset (Distance from Start) | Blockage (%) | Grease (%) | Sags (%) | Fine Roots | Condition |

| 2 | MH203 | MH204 | LU‐103 | Circumferential Crack – 2.0, 9.9, 94.0, 166.3, 320.1, 338.1 Longitudinal Crack‐ 19.1, 33.7, 63.8, 75.8, 172.3, 181.3, 229.6, 232.8, 256.9, 322.8 | 5 | 5 | Fair | ||

| 3 | Multiple Crack‐ 36.8, 60.9, 66.9, 100.2, 106.2, 277.9, 298.9, 346.9, 356.1 Circumferential Fracture– 57.9 Joint Offset‐ 129.9, 133.2 Tap Break in‐ 322.2, 366.5 Tap Factory‐ 52.7 | ||||||||

| 4 | MH204 | MH204A | LU‐104 | Broken – 51.6, 72.6 Circumferential Crack‐ 57.6, 183.7, 229.1, 261.9, 295.0 Longitudinal Crack‐ 48.6, 105.8 Multiple Crack‐ 3.5, 9.3, 27.4, 45.5, 129.6, 153.8, 156.7, 159.7, 174.7, 256.2, 271.0 280.0 | 5 | Fair | |||

| 5 | Circumferential Fracture‐ 192.9 Joint Offset‐ 241.0 Tap Break in‐ 223.7 Tap Factory‐ 142.4, 230.0 | ||||||||

| 6 | MH204A | MH3 | LU‐104A | Circumferential Crack‐ 28.8, 37.6, 58.8, 67.8 Longitudinal Crack‐ 7.9, 25.7, 49.8 | 5 | 5 | Fair | ||

| 7 | Multiple Crack‐ 4.9, 13.8, 19.7 Longitudinal Fracture‐ 89.1 Multiple Fracture‐ 89.4 Joint Offset‐ 85.7 Tap Factory‐ 5.7 | ||||||||

3.9.1.3 Topeka Avenue

Two sanitary sewer pipe segments were inspected at Topeka Avenue. They ranged in condition from fair to good. The segment of pipe between MH220 and MH 219, and between MH219 and MH212 consisted of several locations of pipe in fair condition which contained lining failure undercut and overcut, and lining failure defective with a defect ranging from 1 to 2. Also several areas of these pipe segments contained 5% sags. In summary, the average condition of the pipes in this area was good.

Table 1-5: Topeka Avenue Sanitary Sewer

| Historic ID | - | Section ID | Description | - | - | - | - | - | |

|---|---|---|---|---|---|---|---|---|---|

| 1 | Start Location | End Location | Pipe Segment Reference | Broken, Cracks, Fracture, and Joint offset (Distance from Start) | Blockage (%) | Grease (%) | Sags (%) | Fine Roots | Condition |

| 2 | MH220 | MH219 | LU‐105 | Lining Failure Undercut‐ 104.6, 140.3, 298.0, 346.6, 383.0, 404.0, 464.1, 479.1, 488.1, 491.1 Lining Failure Overcut‐ 337.4, 392.0 Lining Failure Defective End –543.0 | 5 | Good | |||

| 3 | MH219 | MH212 | LU‐106 | Lining Failure Undercut‐66.4, 365.0, 400.8 | 5 | Good | |||

3.9.1.4 Cleveland Avenue

Two sanitary sewer pipe segments were inspected at Cleveland Avenue. They ranged in condition from poor to fair. The segment of pipe between MH222 and MH221, and between MH221 and MH213 consisted of several locations of pipe in poor condition which contained broken, crack circumferential , crack longitudinal, crack and fracture multiple, joint offset and tap factory defective with a defect ranging from 1 to 5. The pipe in fair condition is in similar situation as noted for Bailey Avenue. Also several areas of these pipe segments contained 10% grease, 10% sags and fine roots. In summary, the average condition of the pipes in this area was poor

Table 1-6: Cleveland Avenue Sanitary Sewer

| Historic ID | - | Section ID | Description | - | - | - | - | - | |

|---|---|---|---|---|---|---|---|---|---|

| 1 | MH222 | MH221 | LU‐107A | Broken‐ 30.3 Circumferential Crack – 3.0, 78.6, 127.7, 130.5, 161.0, 167.0, 203.6, 238.9, 248.0, 263.3, 275.6, 335.5, 344.7 Longitudinal Crack‐ 14.6, 36.0, 75.7, 100.2, 109.2, 158.1, 226.6 Multiple Crack‐ 118.3 | Fair | ||||

| 2 | Multiple Fracture‐ 33.1 Joint Offset‐18.1, 21.1, 134.0, 203.6, 351.0 Tap Factory‐ 160.1 | ||||||||

| 3 | MH221 | MH213 | LU‐107 | Broken‐ 9.2, 308.6 Circumferential Crack‐ 208.4, 220.7, 214.9, 226.5, 248.0, 299.7, 351.4, 402.1, 417.4, 420.4, 426.5, 432.5, 438.6, 441.7, 469.2, 475.3, 496.4, 508.7, 537.0 Longitudinal Crack‐ 189.9, 557.7 | 10 | 10 | Y | Poor | |

| 4 | Multiple Crack‐174.8, 196.2, 551.8, 554.4, 566.7 Circumferential Fracture‐51.4, 305.9, 314.8, 360.6, 371.8, 374.6, 377.6, 380.9, 393.1, 405.2, 408.2 Multiple Fracture‐1.5, 112.0, 183.7, 186.9, 223.5, 232.6, 366.7, 369.7, 396.0, 399.0, 505.5 | ||||||||

| 5 | Joint Offset‐182.0, 254.1, 383.8, 513.7 Tap Factory‐ 25.0 | ||||||||

3.9.1.5 Brooklyn Avenue

Two sanitary sewer pipe segments were inspected at Brooklyn Avenue. They ranged in condition from poor to fair. The segment of pipe between MH224 and MH 223, and between MH223 and MH214 consisted several locations of pipe in poor condition which contained broken soil visible, crack and fracture circumferential , crack longitudinal, crack and fracture multiple, joint offset and tap factory defective with a defect ranging from 3 to 5. The pipe in fair condition is in similar situation as noted for Bailey Avenue. Also several areas of these pipe segments contained 5% grease, 5% sags and fine roots. In summary, the average condition of the pipes in this area was poor.

Table 1-7: Brooklyn Avenue Sanitary Sewer

| Historic ID | - | Section ID | Description | - | - | - | - | - | |

|---|---|---|---|---|---|---|---|---|---|

| 1 | Start Location | End Location | Pipe Segment Reference | Broken, Cracks, Fracture, and Joint offset (Distance from Start) | Blockage (%) | Grease (%) | Sags (%) | Fine Roots | Condition |

| 2 | MH224 | MH223 | LU‐108A | Broken Soil Visible‐ 235 Longitudinal Crack‐ 21.6, 101.3, 519.9 Multiple Crack‐ 49.3, 283.5, 319.7, 432.1 Circumferential Fracture‐ 1.7, 43.1, 98.1,152.8, 155.8, 201.4, 204.3, 292.5 | 5 | 5 | Poor | ||

| 3 | Joint Offset‐ 16.0, 58.6, 478.0, 523.5 Tap Factory‐ 512.0 | ||||||||

| 4 | MH223 | MH214 | LU‐108 | Broken‐ 383.0 Broken Soil Visible‐ 239.5, 425.6, 568.8 Circumferential Crack‐ 197.3, 224.4, 309.9, 28.1, 370.8, 401.3, 419.5, 34.9, 541.6, 563.0 Longitudinal Crack‐ 14.9 | 5 | 5 | Y | Poor | |

| 5 | Multiple Crack‐ 102.5, 190.9, 343.1, 483.4 Circumferential Fracture‐ 33.7,194.1, 285.4, 303.7, 459.1,502.0 Multiple Fracture‐ 3.0, 135.5, 236.7, 377.0 Joint Offset‐ 126.0 Tap Factory‐ 216.3, 377.8 | ||||||||

3.9.1.6 Boston Avenue

Two sanitary sewer pipe segments were inspected at Boston Avenue. They ranged in condition from poor to fair. The segment of pipe between MH226 and MH225, and between MH225 and MH215 consisted several locations of pipe in poor condition which contained broken, crack and fracture circumferential, crack and fracture longitudinal, crack and fracture multiple, tap break in and tap factory defective with a defect ranging from 3 to 5. The pipe in fair condition is in similar situation as noted for Bailey Avenue. Also several areas of these pipe segments contained 5% grease and fine roots. In summary, the average condition of the pipes in this area was poor.

Table 1-8: Boston Avenue Sanitary Sewer

| Historic ID | - | Section ID | Description | - | - | - | - | - | |

|---|---|---|---|---|---|---|---|---|---|

| 1 | Start Location | End Location | Pipe Segment Reference | Broken, Cracks, Fracture, and Joint offset (Distance from Start) | Blockage (%) | Grease (%) | Sags (%) | Fine Roots | Condition |

| 2 | MH226 | MH225 | LU‐109A | Broken‐ 26.6 Circumferential Crack – 45.2, 64.7, 91.9, 107.4, 111.5, 152.5, 162.2, 202.1, 205, 216.9, 314.3, 342.0, 369.2, 372.3, 381.2, 412.0, 454.1, 487.9 Longitudinal Crack‐ 222.9, 256.6, 271.7 Multiple Crack‐ 67.2, 98.1, 158.6, 168.2 | 5 | Y | Poor | ||

| 3 | 183.5, 232.1, 393.5, 421.1, 445.2 Circumferential Fracture‐ 293.1, 448.3 Multiple Fracture‐190.1, 192.9, 442.2 Tap Break in‐ 112.3 | ||||||||

| 4 | MH225 | MH215 | LU‐109 | Broken‐ 171.5 Circumferential Crack‐ 72.6, 84.7, 106.0 Longitudinal Crack‐ 38.8, 228.0 Multiple Crack‐ 164.0, 167.2, 185.6, 394.8, 416.3, 461.7, 474.1, 504.1 Circumferential Fracture‐ 11.3, 81.9, 93.7, 236.9, 328.5 | 5 | Y | Poor | ||

| 5 | Multiple Fracture‐ 87.8, 91.0 Tap Break in‐ 171.5, 479.3 Tap Factory‐ 91.7, 171.5 | ||||||||

3.9.1.7 Wabash Avenue

One sanitary sewer pipe segments were inspected at Wabash Avenue. They ranged in condition from poor to fair. The segment of pipe between MH218 and MH217, consisted several locations of pipe in poor condition which contained broken, crack circumferential , crack and fracture longitudinal, crack and fracture multiple, joint offset and tap break in with a defect ranging from 3 to 4. The pipe in fair condition is in similar situation as noted for Bailey Avenue. Also several areas of these pipe segments contained 5% sags. In summary, the average condition of the pipes in this area was fair.

Table 1-9: Wabash Avenue Sanitary Sewer

| Historic ID | - | Section ID | Description | - | - | - | - | - | |

|---|---|---|---|---|---|---|---|---|---|

| 1 | Start Location | End Location | Pipe Segment Reference | Broken, Cracks, Fracture, and Joint offset (Distance from Start) | Blockage (%) | Grease (%) | Sags (%) | Fine Roots | Condition |

| 6 | MH218 | MH217 | LU‐110 | Broken‐ 404.5 Circumferential Crack‐ 60.7, 94.1, 100.1, 447.0, 538.3t Longitudinal Crack‐ 81.6, 197.5, 221.9, 285.2, 544.7 Multiple Crack‐ 228.2, 315.9, 343.5, 450.2, 474.6, 477.3, 531.7 | 5 | Fair | |||

| 7 | Longitudinal Fracture‐ 478.0 Multiple Fracture‐ 361.1 Joint Offset‐ 97.4, 136.8, 146.0, 282.6, 502.0 Tap Break in‐ 104.2, 313.8, 452.7 | ||||||||

3.9.1.8 Bascom Avenue

Two sanitary sewer pipe segments were inspected at Bascom Avenue. They ranged in condition from poor to fair. The segment of pipe between MH103 and MH102, and between MH102 and MH101 consisted several locations of pipe in poor condition which contained broken soil visible, crack and fracture circumferential, crack longitudinal, with a defect ranging from 1 to 5. The pipe in fair condition is in similar situation as noted for Bailey Avenue. Also several areas of these pipe segments contained 5% sags. In summary, the average condition of the pipes in this area was fair.

Table 1-10: Bascom Avenue Sanitary Sewer

| Historic ID | - | Section ID | Description | - | - | - | - | - | |

|---|---|---|---|---|---|---|---|---|---|

| 1 | Start Location | End Location | Pipe Segment Reference | Broken, Cracks, Fracture, and Joint offset (Distance from Start) | Blockage (%) | Grease (%) | Sags (%) | Fine Roots | Condition |

| 8 | MH103 | MH102 | HU‐101 | Broken Soil Visible‐ 333.8 Circumferential Crack‐ 2.5, 69.7, 75.5t Longitudinal Crack‐ 26.1, 182.2 Circumferential Fracture‐ 41.5, 134.9, 196.3 Joint Offset‐ 237.3, 273.4, 325.2, 378.2 | 5 | Fair | |||

| 9 | MH102 | MH101 | HU‐102 | Broken‐ 11.6 ft Circumferential Crack‐ 3.5, 58.7,102.6,120.6, 388.3 Longitudinal Crack‐ 154.6 Circumferential Fracture‐ 218.2, 323.5 | 5 | Poor | |||

3.9.1.9 Laswell Avenue

Two sanitary sewer pipe segments were inspected at Laswell Avenue. They ranged in condition from poor to fair. The segment of pipe between MH106 and MH105, and between MH104 and MH01 consisted several locations of pipe in poor condition which contained broken, crack circumferential , crack longitudinal, crack and fracture multiple, hinge and spiral crack, joint offset and tap factory defective with a defect ranging from 1 to 5. The pipe in fair condition is in similar situation as noted for Bailey Avenue. Also several areas of these pipe segments contained 5% grease and 5% sags. In summary, the average condition of the pipes in this area was poor.

Table 1-11: Laswell Avenue Sanitary Sewer

| Historic ID | - | Section ID | Description | - | - | - | - | - | |

|---|---|---|---|---|---|---|---|---|---|

| 1 | Start Location | End Location | Pipe Segment Reference | Broken, Cracks, Fracture, and Joint offset (Distance from Start) | Blockage (%) | Grease (%) | Sags (%) | Fine Roots | Condition |

| 10 | MH106 | MH105 | LU‐201 | Broken‐ 203.7 Circumferential Crack ‐ 77.6, 219.4,258.0, 336.7, 348.6, 435.0 Longitudinal Crack‐ 122.8, 254.3, 281.0 Hinge Crack‐ 165.6, 254.3 Multiple Crack– 118.5, 148.4, 154.4, 165.6, 187.9, 379.9 | Poor | ||||

| 11 | Spiral Crack‐ 271.4 Joint Offset‐ 118.5, 122.8, 154.4, 156.2, 165.6, 200.6, 219.3, 225.2, 254.3 Tap Factory‐ 118.1,150.3,155.4, 187.9,199.5, 262.4, 264.6, 281.4, 302.6, 319.4, 349.6, 379.0, 390.0, 400.8, 431.0, 435.4, 437.8 | ||||||||

| 12 | MH104 | MH01 | LU‐203 | Broken– 297.2 Circumferential Crack‐ 5.8, 383.0 Multiple Fracture‐ 8.4, 83.4, 159.8, 213.5 Joint Offset‐ 49.5, 115.1 Tap Factory‐ 297.8 | 5 | 5 | Fair | ||

3.9.2.0 Vaughn Avenue

Three sanitary sewer pipe segments were inspected at Vaughn Avenue. They ranged in condition from poor to fair. The segment of pipe between MH109 and MH108, and between MH108 and MH107 and between MH107 and MH3 consisted several locations of pipe in poor condition which contained crack and fracture circumferential, crack longitudinal, crack multiple, joint offset with a defect ranging from 1 to 5. The pipe in fair condition is in similar situation as noted for Bailey Avenue. Also several areas of these pipe segments contained 5% grease and 5% sags. In summary, the average condition of the pipes in this area was fair.

Table 1-12: Vaughn Avenue Sanitary Sewer

| Historic ID | - | Section ID | Description | - | - | - | - | - | |

|---|---|---|---|---|---|---|---|---|---|

| 1 | Start Location | End Location | Pipe Segment Reference | Broken, Cracks, Fracture, and Joint offset (Distance from Start) | Blockage (%) | Grease (%) | Sags (%) | Fine Roots | Condition |

| 13 | MH109 | MH108 | LU‐204 | Circumferential Crack – 2.0 Longitudinal Crack‐ 287.2, 350.5 Circumferential Fracture‐ 63.7, 443.1 | 5 | 5 | Fair | ||

| 14 | MH108 | MH107 | LU‐205 | Circumferential Crack‐ 2.0, 9.9, 28.9, 130.6, 140.3, 171.2, 180.3, 213.1, 239.9, 246.2, 255.8, 288.8, 319.8, 328.8, 336.8 Longitudinal Crack‐ 136.3 Multiple Crack‐ 360.7 | 5 | 5 | Fair | ||

| 15 | Circumferential Fracture‐ 4.4, 230.9, 390.7 Joint Offset‐ 121.4, 282.9, 386.0 | ||||||||

| 16 | MH107 | MH3 | LU‐206 | Circumferential Crack‐ 2.8, 36.5, 69.5, 85.3, 122.2, 432.2 Longitudinal Crack‐ 45.3, 74.2, 82.2, 114.3 Multiple Crack‐ | 5 | Y | Poor | ||

| 17 | 4.5, 31.4 Circumferential Fracture‐ 12.5 Longitudinal Fracture‐ 12.5, 57.4, 383.8 Multiple Fracture‐ 53.8, 203.4 Joint Offset‐ 260.5, 432.2 | ||||||||

3.9.2.1 Arleta Avenue

Three sanitary sewer pipe segments were inspected at Arleta Avenue. They ranged in condition from poor to fair. The segment of pipe between MH112 and MH111, and between MH111 and MH110, and between MH110 and MH4 consisted several locations of pipe in poor condition which contained crack and circumferential, crack longitudinal, crack multiple, joint offset and tap break in with a defect ranging from 1 to 5. The pipe in fair condition is in similar situation as noted for Bailey Avenue. Also several areas of these pipe segments contained 5% grease, 5%‐ 10% sags and fine roots. In summary, the average condition of the pipes in this area was fair.

Table 1-13: Arleta Avenue Sanitary Sewer

| Historic ID | - | Section ID | Description | - | - | - | - | - | |

|---|---|---|---|---|---|---|---|---|---|

| 1 | Start Location | End Location | Pipe Segment Reference | Broken, Cracks, Fracture, and Joint offset (Distance from Start) | Blockage (%) | Grease (%) | Sags (%) | Fine Roots | Condition |

| 18 | MH112 | MH111 | LU‐207 | Circumferential Crack‐ 2.0, 46.6, 326.7, 337.6, 363.5 Longitudinal Crack‐ 9.2, 20.4,138.2 Circumferential Fracture‐ 48.5, 200.5, 286.9, 340.7, | 10 | Fair | |||

| 19 | 392.7 Joint Offset‐ 14.5, 296.0 Tap Break in‐ 136.7 | ||||||||

| 20 | MH111 | MH110 | LU‐208 | Circumferential Crack‐ 67.4, 90.4, 110.4, 212.8, 393.8 Longitudinal Crack‐27.2, 293.6 Multiple Crack‐ 78.6, 168.6, 179.5 Circumferential Fracture‐ 122.1, 300.0 Joint Offset‐ 30.0, 54.4 | 5 | 5 | Y | Good | |

| 21 | MH110 | MH4 | LU‐209 | Broken‐ 250.6 Broken Soil Visible‐381.9 Circumferential Crack‐9.1, 18.1, 26.1, 91.2, 108.2, 151.4, 430.2 Longitudinal Crack‐ 3.0, 17.6, 57.1, 65.5, 66.2, 71.2, 82.2, 111.2 Circumferential Fracture‐ 307.6 Longitudinal Fracture‐ 148.4 | 5 | 5 | Y | Fair | |

| 22 | Multiple Fracture‐ 203.5 Joint Offset‐ 161.3, 406.2 Tap Break in‐ 110.4 | ||||||||

3.9.2.2 Raymond Avenue

Three sanitary sewer pipe segments were inspected at Raymond Avenue. They ranged in condition from poor to fair. The segment of pipe between MH115 and MH114, and between MH114 and MH113, and between MH113 and MH05 consisted several locations of pipe in poor condition which contained lining failure bulges, lining failure under service, wrinkle lining, joint offset and tap factory defective with a defect ranging from 2 to 4. The pipe in fair condition is in similar situation as noted for Bailey Avenue. Also several areas of these pipe segments contained 5% grease, 15%‐20% sags. In summary, the average condition of the pipes in this area was poor.

Table 1-14: Raymond Avenue Sanitary Sewer

| Historic ID | - | Section ID | Description | - | - | - | - | - | |

|---|---|---|---|---|---|---|---|---|---|

| 1 | Start Location | End Location | Pipe Segment Reference | Broken, Cracks, Fracture, and Joint offset (Distance from Start) | Blockage (%) | Grease (%) | Sags (%) | Fine Roots | Condition |

| 75 | FI | MH137 | LU‐114 | Circumferential Crack ‐65.0 Longitudinal Crack‐ 14.0, 17.1, 25.9, 35.0, 41.0, 68.1, 77.2, 137.4, 213.6, 223.0 Multiple Crack – 8.0, 11.0, 19.9, 80.1, 95.1, 101.1, 107.1, 109.8, 131.5, 134.3, 151.8, 155.3, 161.4, | Poor | ||||

| 85 | MH115 | MH114 | HU‐138 | Lining Failure Bulges‐ 219.0, 235.7 Lining Failure Under Service‐ 22.9, 167.5 Joint Offset‐ 106.9, 109.1 Tap Factory‐ 96.1, 102.5, 117.7, 127.4, 145.7, 154.7, 157.7, 160.8, 167.5, 226.1, 236.1 Wrinkled Lining‐ 219, 237.1 | 15‐ 20 | Poor | |||

| 86 | MH114 | MH113 | HU‐139 | Lining Failure Bulges – 373.1 Joint Offset‐ 64.0 Tap Factory‐ 18.5, 28.0, 58.9, 65.9, 90.0, 111.9, 145.9, 241.7, 254.1, 303.8, 328.5, 378.2, 387.5, 396.9 | 5 | Poor | |||

| 87 | MH113 | MH05 | HU‐140 | Lining Failure Bulges‐ 223.0 | 5 | 5 | Poor | ||

| 88 | Tap Factory‐ 26.7, 101.2, 142.4, 144.4, 153.6, 157.2, 194.4, 197.1, 268.3 | ||||||||

3.9.2.3 Irving Avenue

Three sanitary sewer pipe segments were inspected at Irving Avenue. They ranged in condition from poor to fair. The segment of pipe between MH303 and MH302, and between MH302 and MH301, and between MH301 and MH6 consisted several locations of pipe in poor condition which contained broken, crack and fracture circumferential, crack and fracture longitudinal, crack and fracture multiple, joint angular, joint offset and tap factory defective with a defect ranging from 2 to 5. Also several areas of these pipe segments contained 5% grease and fine roots. In summary, the average condition of the pipes in this area was poor.

Table 1-15: Irving Avenue Sanitary Sewer

| Historic ID | - | Section ID | Description | - | - | - | - | - | |

|---|---|---|---|---|---|---|---|---|---|

| 1 | Start Location | End Location | Pipe Segment Reference | Broken, Cracks, Fracture, and Joint offset (Distance from Start) | Blockage (%) | Grease (%) | Sags (%) | Fine Roots | Condition |

| 27 | MH303 | MH302 | LU‐210 | Broken‐ 282.6 Circumferential Crack ‐ 123.3, 417.8 Longitudinal Crack‐ 81.2, 125.8, 169.2, 216.8, 337.2, 347.8, 350.2 Multiple Crack– 43.5 Longitudinal Fracture‐ 384.5 Joint Angular‐ 443.7 | Y | Poor | |||

| 28 | Joint Offset‐ 300.1, 398.5, 434.6, 440.9, 444.0 | ||||||||

| 29 | MH302 | MH301 | LU‐211 | Broken‐ 228.8, 233.2 Circumferential Crack‐ 17.0, 22.1, 98.8, 198.1, 201.0, 247.2, 268.7, 271.5, 398.0 Longitudinal Crack‐ 51.0, 66.8, 107.8, 113.7, 162.3, 167.9, 238.9, 245.0, 256.1, 268.7 Multiple Crack‐ 3.0 | 5 | Poor | |||

| 30 | Circumferential Fracture‐ 7.1, 145.0, 253.5 Longitudinal Fracture‐ 125.7, 263.7 Multiple Fracture‐ 53.9 Tap Factory‐ 126.6, 228.8 | ||||||||

| 31 | MH301 | MH6 | LU‐212 | Circumferential Crack‐ 54.3, 84.2, 162.5, 177.7, 225.5, 261.1, 321.0 Longitudinal Crack‐ 13.8, 14.9, 16.3, 30.2, 39.3, 59.3, 69.4, 72.2, 90.1, 104.2, 142.1, 168.4, 211.3, 272.3, 284.3, 303.7, 336.3, 343.2, 358.4 | 5 | Y | Fair | ||

| 32 | Multiple Crack‐ 19.3, 45.3, 51.2, 106.3, 153.4, 174.6, 187.6, 198.9, 349.4 | ||||||||

| 33 | Spiral Crack‐ 196.1 Circumferential Fracture‐ 171.6 Longitudinal Fracture‐ 179.9 Joint Offset‐ 422.5 Tap Factory‐ 26.3, 8.2, 146.2, 178.8, 184.1, 188.9, 224.4, 302.6, 342.2 | ||||||||

3.9.2.4 Leland Avenue

Four sanitary sewer pipe segments were inspected at Leland Avenue. They ranged in condition from poor to fair. The segment of pipe between FI and MH134, and between MH134 and MH133, and between MH133 and MH305, and between MH305 and MH304, and between MH304 and MH7 consisted several locations of pipe in poor condition which contained broken, crack and fracture circumferential, crack and fracture longitudinal, crack and fracture multiple, spiral fracture, joint offset and tap factory defective with a defect ranging from 2 to 5. The pipe in fair condition is in similar situation as noted for Bailey Avenue. Also several areas of these pipe segments contained 5‐10% grease, 5%‐10% sags and fine roots. In summary, the average condition of the pipes in this area was fair.

Table 1-16: Leland Avenue Sanitary Sewer

| Historic ID | - | Section ID | Description | - | - | - | - | - | |

|---|---|---|---|---|---|---|---|---|---|

| 1 | Start Location | End Location | Pipe Segment Reference | Broken, Cracks, Fracture, and Joint offset (Distance from Start) | Blockage (%) | Grease (%) | Sags (%) | Fine Roots | Condition |

| 34 | FI | MH134 | LU‐122 | Circumferential Crack – 62.0, 146.1, 176.4, 188.8, 194.0 | 5 | 5 | Y | Fair | |

| 35 | Longitudinal Crack‐ 43.7, 83.4, 196.8 Multiple Crack– 240.9 Circumferential Fracture‐ 143.9 Multiple Fracture– 26.6, 214.0 Tap Factory‐ 239.7, 241.6 | ||||||||

| 36 | MH134 | MH133 | LU‐123 | Broken– 192.8, 528 Circumferential Crack‐ 55.4, 64.5, 108.0, 155.6, 178.7, 230.1, 291.8, 335.4, 402.7, 561.1, 597.4, 618.6 Longitudinal Crack‐ 6.5, 379.5, 410.5, 437.1 Multiple Crack‐ 43.2, 70.4, 152.3, 163.4, 309.0, 332.3, 407.9, 557.2, 576.5 | 10 | 5 | Y | Fair | |

| 37 | Circumferential Fracture‐ 464.4 Multiple Fracture‐282.8, 338.5 Joint Offset‐ 96.1, 341.0 Tap Factory‐ 86.6, 130.1, 179.4, 221.2, 223.0, 279.7, 281.8, 331.1, 378.6, 383.6, 406.8, 559.9 | ||||||||

| 38 | MH133 | MH305 | LU‐213 | Circumferential Crack‐ 443.0 Longitudinal Crack‐ 135.5, 154.1,196.0, 198.9 | 5 | 10 | Y | Fair | |

| 39 | 256.8, 301.9, 344.7, 347.9, 383.1 Multiple Crack‐ 92.9, 239.7, 287.8, 350.2 Longitudinal Fracture‐ 77.5, 112.6, 115.6, 382.9 Spiral Fracture‐ 386.5 Joint Offset‐ 440.2, 449.4 Tap Factory‐ 64.9, 217.8, 258.0, 289.3, 352.0 | ||||||||

| 40 | MH305 | MH304 | LU‐214 | Broken‐ 163.6, 249.7 Circumferential Crack – 45.2, 77.1, 209.2 Longitudinal Crack‐ 139.9, 266.6, 268.6, 298.7 Multiple Crack– 92.2, 224.0, 241.8, 292.6, 304.5, 386.0 Longitudinal Fracture‐ 162.6 | 5 | 5 | Poor | ||

| 41 | Multiple Fracture‐ 56.3 Joint Offset‐ 390.1 Tap Factory‐ 4.5, 52.1, 78.2, 89.1, 102.0, 136.9, 248.6, 256.7, 267.7, 326.3, 371.1 | ||||||||

| 42 | MH304 | MH7 | LU‐215 | Circumferential Crack‐ 27.8, 56.1, 151.4 Longitudinal Crack‐ 45.1, 79.1, 118.8, 164.9, | 5 | 5 | Y | Fair | |

3.9.2.5 Ruthland Avenue

Six sanitary sewer pipe segments were inspected at Ruthland Avenue. They ranged in condition from poor to fair. The segment of pipe between FI and MH310, and between MH310 and MH309, and between MH309 and MH308, and between MH308 and SS, and between SS and MH307, and between MH307 and MH08A consisted several locations of pipe in poor condition which contained broken soil visible, crack and fracture circumferential, crack and fracture longitudinal, crack and fracture multiple, joint offset and tap break in and tap factory defective with a defect ranging from 1 to 5. The pipe in fair condition is in similar situation as noted for Bailey Avenue. Also several areas of these pipe segments contained 5%‐10% grease, 5%‐10% sages and fine roots. In summary, the average condition of the pipes in this area was fair.

Table 1-17: Ruthland Avenue Sanitary Sewer

| Historic ID | - | Section ID | Description | - | - | - | - | - | |

|---|---|---|---|---|---|---|---|---|---|

| 1 | Start Location | End Location | Pipe Segment Reference | Broken, Cracks, Fracture, and Joint offset (Distance from Start) | Blockage (%) | Grease (%) | Sags (%) | Fine Roots | Condition |

| 45 | FI | MH310 | LU‐216 | Circumferential Crack – 10.2, 110.2, 119.0, 152.1, 208.5, 242.6 Longitudinal Crack‐ 55.7, 116.4, 145.8, 211.5 Longitudinal Fracture‐119.0 Joint Offset‐ 19.5, 116.4,196.5, 258.0 | 5 | Y | Fair | ||

| 46 | MH310 | MH309 | LU‐217 | Broken Soil Visible‐556.0 Circumferential Crack‐ 23.4, 32.6, 69.9, 85.2, 118.7, 187.1, 325.5, 350.6, 395.4, 456.9, 485.0, 509.1, 515.5, 531.5, 573.0 Longitudinal Crack‐ 38.7, 43.9, 135.8, 468.9 Circumferential Fracture‐ 45.6, 76.1, 97.5 | 5-10 | Y | Fair | ||

| 47 | Multiple Fracture‐ 512.3 Joint Offset‐ 275.7, 615.5 Tap Factory‐ 134.5 | ||||||||

| 48 | MH309 | MH308 | LU‐218 | Broken Soil Visible‐ 40.1 Circumferential Crack‐ 3.5, 106.0, 259.2, 271.7 Longitudinal Crack‐ 6.6, 114.9, 145.5 Multiple Crack‐ 9.0, 63.0, 79.9, 99.9, 296.1, 320.1 Circumferential Fracture‐ 96.7 | 5 | 5 | Y | Fair | |

| 49 | Multiple Fracture‐ 186.7 Joint Offset‐ 46.2, 350 Tap Break in‐ 220.7 Tap Factory‐ 87.3 | ||||||||

| 50 | MH308 | SS | LU‐219 | Circumferential Crack – 87.6, 121.7, 238.8 Longitudinal Crack‐ 3.5, 27.5, 249.2 Multiple Crack‐ 38.7, 96.7, 109.6, 147.8, 158.6 Longitudinal Fracture‐ 195.6 Multiple Fracture‐ 7.7 | 10 | 5 | Y | Fair | |

| 51 | SS | MH307 | LU‐220 | Circumferential Crack ‐ 167.3, 184.1, 190.2 Longitudinal Crack‐ 83.8, 124.5 Circumferential Fracture‐ 170.4 Joint Offset‐ 32.7 | 5 | Y | Fair | ||

| 52 | MH307 | MH08A | LU‐221 | Circumferential Crack ‐ 5.3,18.2, 47.0, 54.4, 88.8, 139.7,149.8, 153.8, 168.7,175.2, 214.0, 420.3 Longitudinal Crack‐37.0, 200.7, 342.4 Multiple Crack‐ 109.8, 201.9, 220.1, 236.8, 243.0, 308.5, 329.0, 379.6 | 5 | 5 | Y | Fair | |

| 53 | Circumferential Fracture‐ 62.0, 257.0 Longitudinal Fracture‐ 420.3 Multiple Fracture ‐227.8 Joint Offset‐ 131.4, 146.4, 186.7, 275.2, 420.3 Tap Factory‐ 355.1 | ||||||||

3.9.2.6 Clifton Avenue

Three sanitary sewer pipe segments were inspected at Clifton Avenue. They ranged in condition from poor to fair. The segment of pipe between MH315 and MH314, and between MH314 and MH313, and between MH313 and MH09A consisted several locations of pipe in poor condition which contained crack and fracture circumferential, crack longitudinal, crack and fracture multiple, joint offset and tap break in and tap factory defective with a defect ranging from 1 to 4. The pipe in fair condition is in similar situation as noted for Bailey Avenue. Also several areas of these pipe segments contained 10% grease, 5% sag and fine roots. In summary, the average condition of the pipes in this area was fair.

Table 1-18: Clifton Avenue Sanitary Sewer

| Historic ID | - | Section ID | Description | - | - | - | - | - | |

|---|---|---|---|---|---|---|---|---|---|

| 1 | Start Location | End Location | Pipe Segment Reference | Broken, Cracks, Fracture, and Joint offset (Distance from Start) | Blockage (%) | Grease (%) | Sags (%) | Fine Roots | Condition |

| 54 | MH315 | MH314 | LU‐223 | Circumferential Crack ‐ 100.9, 245.5 Longitudinal Crack‐ 55.1, 106.7, 124.0 ,133.1, 313.2 | 10 | 5 | Y | Fair | |

| 55 | Circumferential Fracture‐ 37.1 Joint Offset‐ 152.6, 304.5 | ||||||||

| 56 | MH314 | MH313 | LU‐224 | Circumferential Crack‐ 9.8, 11.9, 25.0, 91.2, 100.7, 122.9, 143.8, 160.0, 165.9, 201.8, 220.0, 267.6, 309.8, 317.5, 347.5, 353.3, 376.8, 419.9, 436.9 | 10 | 5 | Y | Fair | |

| 57 | Longitudinal Crack‐ 86.1, 148.5, 407.6 Multiple Crack‐ 19.9, 258.6, 366.9 Circumferential Fracture‐ 332.0 Multiple Fracture‐ 426.0 Joint Offset‐ 335.5 Tap Break in‐ 315.9 Tap Factory‐ 90.6, 433 | ||||||||

| 58 | MH313 | MH09A | LU‐225 | Circumferential Crack‐ 15.8, 24.1, 46.8, 59.4, 66.0, 68.1, 85.6, 120.3, 132.4, 192.7, 229.5, 236.1 Longitudinal Crack‐ 307.1 Multiple Crack‐ 55.8, 114.4, 126.2, 141.9, 146.3, 288.1 Joint Offset‐ 189.8, 413.1 | 5 | Y | Fair | ||

3.9.2.7 Leigh Avenue

Three sanitary sewer pipe segments were inspected at Leigh Avenue. They ranged in condition from poor to fair. The segment of pipe between MH318 and MH317, and between MH317 and MH316, and between MH316 and MH10 consisted several locations of pipe in poor condition which contained broken soil visible, crack circumferential , crack and fracture longitudinal, crack and fracture multiple, deformed, joint offset and tap break in and tap factory defective with a defect ranging from 1 to 5. The pipe in fair condition is in similar situation as noted for Bailey Avenue. Also several areas of these pipe segments contained 5% grease, 5% sags and fine roots. In summary, the average condition of the pipes in this area was poor

Table 1-19: Leigh Avenue Sanitary Sewer

| Historic ID | - | Section ID | Description | - | - | - | - | - | |

|---|---|---|---|---|---|---|---|---|---|

| 1 | Start Location | End Location | Pipe Segment Reference | Broken, Cracks, Fracture, and Joint offset (Distance from Start) | Blockage (%) | Grease (%) | Sags (%) | Fine Roots | Condition |

| 59 | MH318 | MH317 | LU‐227 | Circumferential Crack – 5.0, 63.7, 134.9, 390.5, 406.9 Longitudinal Crack‐ 36.3, 275.8, 336.7 Multiple Crack – 13.8, 190.6, 239.1, 412.6 Longitudinal Fracture‐343.7 Tap Break in‐ 413.8 | 5 | 5 | Poor | ||

| 60 | MH317 | MH316 | LU‐228 | Broken Soil Visible– 2.0, 439.5 Circumferential Crack‐ 111.5, 418.2 Longitudinal Crack‐ 200.2, 436.6 Multiple Crack‐ 5.0, 18.0, 52.2, 183.0, 254.7, 282.1, 313.9, 354.4, 395.0 | 5 | Y | Fair | ||

| 61 | Deformed‐ 2.0 Longitudinal Fracture‐ 58.0, 242.4 Multiple Fracture‐ 401.3 Tap Factory‐ 331.5 | ||||||||

| 62 | MH316 | MH10 | LU‐229 | Broken– 3.0, 115.6 Circumferential Crack‐ 17.5, 342.7, 351.6, 370.0, 412.0 Longitudinal Crack‐ 153.3, 209.9, 315.1 | 5 | Poor | |||

| 63 | Multiple Crack‐ 11.3, 22.5, 43.8, 48.7, 51.7, 63.0, 92.5, 101.5, 124.9, 130.5, 138.8, 165.1, 171.3, 188.3, 230.1, 259.2, 293.9, 303.2, 323.2, 376.4 | ||||||||

| 64 | Longitudinal Fracture‐ 2.0 Multiple Fracture‐ 300.1 Joint Offset‐ 308.8, 404.6, 406.8, 410.9 Tap Factory‐ 332.2, 376.8 | ||||||||

3.9.2.8 Richmond Avenue

Three sanitary sewer pipe segments were inspected at Richmond Avenue. They ranged in condition from poor to fair. The segment of pipe between MH321 and MH320, and between MH320 and MH319, and between MH319 and MH11 consisted several locations of pipe in poor condition which contained broken soil visible, crack and fracture circumferential, crack and fracture longitudinal, crack and fracture multiple, joint offset and tap break in and tap factory defective with a defect ranging from 3 to 4. The pipe in fair condition was on the verge of qualifying as being in poor condition because of it contained cracks and fracture circumferential at multiple locations throughout the pipe. Also several areas of these pipe segments contained 5% grease, 5% sags and fine roots. In summary, the average condition of the pipes in this area was fair.

Table 1-20: Richmond Avenue Sanitary Sewer

| Historic ID | - | Section ID | Description | - | - | - | - | - | |

|---|---|---|---|---|---|---|---|---|---|

| 1 | Start Location | End Location | Pipe Segment Reference | Broken, Cracks, Fracture, and Joint offset (Distance from Start) | Blockage (%) | Grease (%) | Sags (%) | Fine Roots | Condition |

| 65 | MH321 | MH320 | LU‐230 | Circumferential Crack ‐ 357.7 Multiple Crack – 5.7, 332.3 Multiple Fracture – 237.6, 369.9 | 5 | 5 | Y | Fair | |

| 66 | MH320 | MH319 | LU‐231 | Broken Soil Visible – 224.6 Circumferential Crack‐ 45.2, 104.9, 137.6, 171.9, 181.3, 201.3, 207.5, 216.3, 253.1, 322.6, 332.1, 352.4, 358.1, 382.0, 389.8, 405.3, 420.3 | 5 | 5 | Y | Fair | |

| 67 | Longitudinal Crack‐ 143.6 Multiple Crack‐ 57.4, 146.8, 294.3, 306.9, 393.3 Multiple Fracture‐ 417.3 Joint Offset‐ 146.8, 175.1 Tap Break in‐ 356.0 | ||||||||

| 68 | MH319 | MH11 | LU‐232 | Broken – 177.7,373.2 Circumferential Crack‐ 137.2, 171.9, 251.1, 260.2 Longitudinal Crack‐93.5, 193.4, 317.5, 318.7, 353.0 Multiple Crack‐ 5.0, 74.4, 103.7, 207.3, | 5 | 5 | Poor | ||

| 69 | 216.5, 231.7, 297.5, 304.5, 306.7 Longitudinal Fracture‐64.9 Multiple Fracture‐ 177.8, 275.1, 373.5 Joint Offset‐ 406.3, 411.3 Tap Break in‐ 375.9 Tap Factory‐ 322.8 | ||||||||

3.9.2.9 Easement between Bascom – Laswell Avenue

Two sanitary sewer pipe segments were inspected in an easement between Bascom – Laswell Avenue. They ranged in condition from poor to fair. The segment of pipe between FI and MH119, and between MH119 and MH118 consisted several locations of pipe in poor condition which contained broken soil visible, crack circumferential , crack longitudinal, crack multiple, joint offset and tap break in and tap factory defective with a defect ranging from 4 to 5. The pipe in fair condition was on the verge of qualifying as being in poor condition because of it contained cracks and fracture circumferential at multiple locations throughout the pipe. Also several areas of these pipe segments contained 5% sag. In summary, the average condition of the pipes in this area was poor.

Table 1-21: Easement between Bascom-Laswell Avenue Sanitary Sewer

| Historic ID | - | Section ID | Description | - | - | - | - | - | |

|---|---|---|---|---|---|---|---|---|---|

| 1 | Start Location | End Location | Pipe Segment Reference | Broken, Cracks, Fracture, and Joint offset (Distance from Start) | Blockage (%) | Grease (%) | Sags (%) | Fine Roots | Condition |

| 70 | FI | MH119 | LU‐112 | Circumferential Crack ‐ 48.0, 134.1, 196.7 Longitudinal Crack‐ 27.5, 81.0 Multiple Crack – 43.1, 45.6 | 5 | Fair | |||

| 71 | Joint Offset‐ 9.1, 15.3, 18.6, 21.4, 24.4, 27.5, 30.6, 33.6, 36.8, 40.0, 43.1, 81.0, 87.1, 96.2, 99.3, 102.3, 111.6, 113.6, 118.8, 121.9, 128.1, 134.1, 137.2, 140.3, 146.5, 149.6, 152.6, 158.7, 164.9, 166.8, 174.8, 177.6, 196.3 | ||||||||

| 72 | MH119 | MH118 | HU ‐141 | Broken– 42.8 Circumferential Crack‐ 42.8, 87.1, 99.5, 102.5, 110.5, 116.7, 143.1, 180.3, 384.7, 512.3, 518.9, 576.8, 601.6 Longitudinal Crack‐ 64.6, 218.3, 281.4, 331.7, 427.3, 467.0 | Poor | ||||

| 73 | Multiple Crack‐ 6.0, 21.4, 119.6, 128.9, 131.0, 131.6,149.4, 161.6, 182.2, 208.9, 221.3, 227.4, 228.3, 229.4, 231.3, 234.2, 243.7, 259.3, 287.4, 299.9, 324.6, 326.5, 347.0, 356.0, 356.1, 368.3, 379.4, 402.9, 406.0, 430.2, 451.6, | ||||||||

| 74 | 463.9, 488.3, 494.3, 497.4, 504.2, 510.6, 516.1, 539.8, 546.4, 549.8, 579.8 Hole 226.4, 227.0, 356.0, 356.1 Hole Soil Visible‐ 430.2 Joint Offset‐ 26.8, 30.9, 33.8, 64.6, 80.8, 143.1, 259.3, 265.3, 268.3, 284.5, 421.5 Tap Factory‐ 230.4, 599.3 | ||||||||

3.9.3.0 Easement between Laswell – Arleta Avenue

Two sanitary sewer pipe segments were inspected in an easement between Laswell – Arleta Avenue. They ranged in condition from poor to worst. The segment of pipe between FI and MH137, and between MH137 and MH117 consisted several locations of pipe in poor condition which contained broken soil visible, crack and fracture circumferential, crack and fracture longitudinal, crack and fracture multiple, hinge and spiral crack, spiral fracture, joint offset and tap factory defective with a defect ranging from 1 to 5. The pipe in poor condition was on the verge of qualifying as being in worst condition because of it contained cracks and fracture circumferential at multiple locations throughout the pipe. Also several areas of these pipe segments contained fine roots. In summary, the average condition of the pipes in this area was poor.

Table 1-22: Easement between Laswell-Arleta Avenue Sanitary Sewer

| Historic ID | - | Section ID | Description | - | - | - | - | - | |

|---|---|---|---|---|---|---|---|---|---|

| 1 | Start Location | End Location | Pipe Segment Reference | Broken, Cracks, Fracture, and Joint offset (Distance from Start) | Blockage (%) | Grease (%) | Sags (%) | Fine Roots | Condition |

| 75 | FI | MH137 | LU‐114 | Circumferential Crack ‐65.0 Longitudinal Crack‐ 14.0, 17.1, 25.9, 35.0, 41.0, 68.1, 77.2, 137.4, 213.6, 223.0 Multiple Crack – 8.0, 11.0, 19.9, 80.1, 95.1, 101.1, 107.1, 109.8, 131.5, 134.3, 151.8, 155.3, 161.4, | Poor | ||||

| 76 | 180.1, 182.0, 204.5, 207.3, 210.5, 232.1, 235.1 Joint Offset‐ 8.0, 11.0, 14.0, 17.1, 19.9, 22.9, 25.9, 28.9, 31.9, 35.0, 38.0, 41.0, 50.1, 56.2, 62.2,65, 68.1,71.1, 77.2, 80.1, 89.1,92.2, 95.1, 97.9 | ||||||||

| 77 | 101.1, 107.1, 110.3, 116.3, 122.3, 128.3, 131.5, 134.3, 137.4, 143.3, 143.3, 146.2, 149.2, 155.3, 158.4, 161.4, 164.5, 167.5, 170.7, 173.9, 176.9, 180.1, 186.0, 195.0, | ||||||||

| 78 | 198.2, 198.2, 201.2, 204.5, 207.3, 210.5, 213.6, 223.0, 232.1, 235.1 Tap Factory‐ 106.3, 148.3, 151.2, 194.0 | ||||||||

| 79 | MH137 | MH117 | LU‐115 | Broken Soil Visible– 120.6, 181.4 Circumferential Crack‐ 52.0, 62.3, 231.8, 289.8, 317.7 Longitudinal Crack‐ 21.8,45.7, 175.5, 221.8, 231.1, 283.6, 286.4, 286.6, 299.2, 490.0, 536.2 | Y | Poor | |||

| 80 | Hinge Crack‐ 18.8, 77.2, 265.0, 305.2, 376.6, 397.9, 407.3, 478.0, 485.0, 499.1, 561.1, 582.4 Multiple Crack‐ 7.0, 30.4, 329.4, 354.9, 357.9, 370.1, 382.9, 385.5, 419.4, 428.7, 456.3, 468.7, 501.2, 524.0, 526.9, 530.0 | ||||||||

| 81 | Spiral Crack‐ 9.8, 46.0, 80.3, 86.4,105.0, 108.1, 114.3, 147.7, 166.3, 178.3, 197.0, 228.2, 253.0, 296.0, 311.4, 320.6, 342.3, 348.4, 363.9, 391.8, 437.8, 444.1, 450.2, 508.4, 526.9, 533.0, 542.3, 570.1, 588.6 | ||||||||

| 82 | Multiple Fracture‐ 181.4, 262.0, 502.2 Spiral Fracture‐ 135.7 Joint Offset‐ 9.8, 88.2, 116.0, | ||||||||

| 83 | 234.8,255.6, 289.7, 299.2, 333.0, 342.3, 376.6, 420.8, 424.2, 433.8, 434.7, 436.2, 444.1, 479.7, 481.3, 485.0, 499.1, 526.9, 526.9, 582.4 | ||||||||

3.9.3.1 Easement between Arleta – Raymond Avenue

Two sanitary sewer pipe segments were inspected in an easement between Arleta – Raymond Avenue. They ranged in condition from poor to fair. The segment of pipe between FI and MH122, and between MH122 and MH116 consisted several locations of pipe in poor condition which contained broken soil visible, crack and fracture circumferential, crack and fracture longitudinal, crack and fracture multiple, deformed, hinge crack, joint offset and tap break in and tap factory defective with a defect ranging from 1 to 5. The pipe in poor condition was on the verge of qualifying as being in worst condition because of it contained cracks and fracture circumferential at multiple locations throughout the pipe. Also several areas of these pipe segments contained 5% sags and fine roots. In summary, the average condition of the pipes in this area was poor.

Table 1-23: Easement between Arleta-Raymond Avenue Sanitary Sewer

| Historic ID | - | Section ID | Description | - | - | - | - | - | |

|---|---|---|---|---|---|---|---|---|---|

| 1 | Start Location | End Location | Pipe Segment Reference | Broken, Cracks, Fracture, and Joint offset (Distance from Start) | Blockage (%) | Grease (%) | Sags (%) | Fine Roots | Condition |

| 89 | FI | MH122 | LU‐116 | Circumferential Crack ‐ 45.0, 63.2, 93.4, 253.1 Longitudinal Crack‐ 23.5, 215.4 | Y | Poor | |||

| 90 | Hinge Crack‐ 42.1, 93.4, 117.6 Multiple Crack – 32.9, 60, 69.1, 71.3, 85.8, 120.6, 139.3, 159.9, 168.0, 177.2, 195.8, 265.6 Longitudinal Fracture‐ 69.1 | ||||||||

| 91 | 11.2, 17.4, 17.4, 23.5, 26.6, 32.9, 35.8, 39.0, 45.2, 48.2, 51.2, 54.3, 57.3, 60.3, 66.4, 69.4, 71.3, 74.4, 77.6, 80.6, 85.8, 88.9, 91.9, 97.1, 100.1, 103.4, 106.4, 109.5, 117.6, 120.6, 126.8, 133.0, 136.2, 139.3, 153.8, 159.9 | ||||||||

| 92 | 163.1, 165.0, 168.0, 177.2, 180.4, 186.5, 189.7, 195.8, 199.0, 204.0, 212.2, 215.4, 218.4, 221.6, 224.5, 227.6, 227.6, 230.6, 236.9, 240.0, 243.1, 245.5, 248.0, 253.1, 262.4, 265.6, 271.8, 274.9, 277.9, 281.0, 283.9, 287.1 | ||||||||

| 93 | Tap Factory‐ 70.3, 93.0, 152.9, 164.1, 199.9, 211.4, 249.1 | ||||||||

| 94 | MH122 | MH116 | LU‐117 | Broken – 20.7, 21.3, 22.3, 331.9, 527.8 Broken Soil Visible‐ 133.7 Circumferential Crack‐ 77.6, 84.1, 87.8, 140.0, 140.7, 207.6, 215.2, | 5 | Y | Poor | ||

| 95 | 216.7, 235.7, 240.9, 265.5, 285.4, 300.5, 312.7, 362.1, 369.9, 399.6, 415.1, 437.2, 455.5, 472.5, 475.7, 489.8, 541.2, 546.1, 549.1, 551.9, 558.3, 604.0, 607.2, 613.3 | ||||||||

| 96 | Longitudinal Crack‐ 50.0, 89.8, 111.4, 126.6, 252.7, 254.5, 376.3, 434.0, 477.9, 480.7, 483.7, 508.0, 514.0 Hinge Crack‐ 84.5, 156.0, 180.6, 209.1 | ||||||||

| 97 | Multiple Crack‐ 24.7, 49.7, 74.1, 74.4, 90.7, 112.4, 127.5, 131.5, 133.9, 135.0, 136.8, 137.4, 154.9, 173.3, 176.4, 218.3, 232.6, 234.6, 239.4, 252.6, 253.1, 253.8, 255.4, 256.0, 379.3, 501.8, 536.0, 564.4, 573.6, 588.8, 619.0 | ||||||||

3.9.3.2 Easement between Raymond – Irving Avenue

Two sanitary sewer pipe segments were inspected in an easement between Raymond – Irving Avenue. They ranged in condition from poor to fair. The segment of pipe between FI and MH126, and between MH126 and MH125 consisted several locations of pipe in poor condition which contained broken soil visible, crack and fracture circumferential , fracture longitudinal, crack multiple, joint offset and tap break in and tap factory defective with a defect ranging from 1 to 5. The pipe in fair condition was on the verge of qualifying as being in poor condition because of it contained cracks and fracture circumferential at multiple locations throughout the pipe. Also several areas of these pipe segments contained 5% sags. In summary, the average condition of the pipes in this area was poor.

Table 1-24: Easement between Raymond-Irving Avenue Sanitary Sewer

| Historic ID | - | Section ID | Description | - | - | - | - | - | |

|---|---|---|---|---|---|---|---|---|---|

| 1 | Start Location | End Location | Pipe Segment Reference | Broken, Cracks, Fracture, and Joint offset (Distance from Start) | Blockage (%) | Grease (%) | Sags (%) | Fine Roots | Condition |

| 102 | FI | MH126 | LU‐118 | Longitudinal Crack‐ 6.8 Joint Offset‐ 10.3, 28.9, 53.5, 53.6, 56.8, 57.0, 66.1, 68.0, 69.2, 72.3, 80.6, 88.7, 97.0, 105.5, 109.1, 115.5, 131.0, 161.3, 165.9, 172.1, 193.9, 211.3, | 5 | Poor | |||

| 103 | 213.7, 228.8, 251.5, 270.2, 276.2 Tap Factory‐ 73.6, 84.8, 90.0, 103.1, 147.9, 165.9, 194.9, 212.9, 247.6 | ||||||||

| 104 | MH126 | MH125 | LU‐119 | Broken – 90.8, 607.4 Broken Soil Visible‐233.4 Circumferential Crack‐ 49.9, 82.6, 84.4, 93.7, 133.4, 149.5, 155.8, 164.9, 182.0, 185.1, 254.2, 271.7, 296.3, 305.4, 308.5, 320.8, 326.5, 332.6, 335.7, 371.3, | Poor | ||||

| 105 | 383.3, 389.2, 418.9, 424.9, 466.8, 469.8, 475.9, 589.5 Longitudinal Crack‐ 121.3, 227.5, 248.1, 275.1, 392.1, 433.8, 442.7 Multiple Crack‐ 28.4, 87.6, 127.3, 197.3, 242.2, 314.4, 323.7, 439.7, | ||||||||

| 106 | 454.7, 514.3, 532.9 Circumferential Fracture‐ 77.4, 598.3, 601.1 Longitudinal Fracture‐ 395.1, 502.5 | ||||||||

| 107 | Multiple Fracture‐224.4, 233.4, 265.8, 317.4, 526.3 Joint Offset‐ 13.1 Tap Break in‐ 180.0, 561.1 Tap Factory‐ 78.5, 134.4, 183.1, 270.3, 285.1, 327.5 | ||||||||

3.9.3.3 Easement between Irving – Leland Avenue

Three sanitary sewer pipe segments were inspected in an easement between Irving – Leland Avenue. These segments of pipe ranged in condition from fair to good. The segment of pipe between FI and MH131, and between MH129A and MH129, and between MH131 and 129 consisted several locations of pipe in fair condition which contained broken soil visible, crack and fracture circumferential, crack and fracture longitudinal, crack and fracture multiple, joint offset and tap break in and tap factory defective with a defect ranging from 2 to 5. The pipe in good condition was on the verge of qualifying as being in fair condition because of it contained cracks and fracture circumferential at multiple locations throughout the pipe. Also several areas of these pipe segments contained 5% grease, 5%‐10% sags and fine roots. In summary, the average condition of the pipes in this area was good.

Table 1-25: Easement between Irving-Leland Avenue Sanitary Sewer

| Historic ID | - | Section ID | Description | - | - | - | - | - | |

|---|---|---|---|---|---|---|---|---|---|

| 1 | Start Location | End Location | Pipe Segment Reference | Broken, Cracks, Fracture, and Joint offset (Distance from Start) | Blockage (%) | Grease (%) | Sags (%) | Fine Roots | Condition |

| 108 | FI | MH131 | LU‐120 | Circumferential Crack ‐5.6, 6.3, 80.3, 89.4, 100.5, 109.5, 172.6, 249.6, 262.0, | 5‐ 10 | Y | Good | ||

| 109 | 277.2, 285.4 Longitudinal Crack‐ 27.7, 48.8 74.0, 134.0, 152.2, 181.8, 223.4, 229.4 Multiple Crack – 3.8, 47.9, 74.0, 86.3, 92.4, 121.8, 140.1, 155.4, 208.0, 211.1, 236.2 | ||||||||

| 110 | Longitudinal Fracture‐48.8, 200.1t Joint Offset‐ 18.4,33.6, 48.8, 52.0, 67.3, 77.2 ,80.3, 121.8, 148.7, 169.5, 191.0, 244.8, 271.0 Tap Factory‐ 248.8 | ||||||||

| 111 | MH129A | MH129 | LU‐121A | Circumferential Crack‐18.6, 58.5, 90.6, 92.4 Longitudinal Crack‐40.2 Multiple Crack‐ 15.2, 61.4, 70.3, 141.2 | 5 | 5 | Y | Good | |

| 112 | Circumferential Fracture‐ 27.8 Joint Offset‐ 84.4, 95.9 Tap Factory‐ 74.5 | ||||||||

| 113 | MH131 | MH129A | LU‐121 | Broken– 45.4 Broken Soil Visible‐113.7 Circumferential Crack‐57.6, 469.0 Longitudinal Crack‐298.3 Circumferential Fracture‐ 187.4, 256.5, 281.0 Multiple Fracture‐232.4 | 5 | Y | Fair | ||

| 114 | Joint Offset‐ 434.0 Tap Break in‐ 256.3 Tap Factory‐ 84.7, 129.3, 183.5, 231.5, 380.1 | ||||||||

3.9.3.4 Forest Avenue

Four sanitary sewer pipe segments were inspected at Forest Avenue. They ranged in condition from fair to good. The segment of pipe between MH216 and MH215, and between MH215 and MH214, and between MH214 and MH213, and between MH213 and MH212 consisted several locations of pipe in fair condition which contained hinge fracture, and tap saddle defective with a defect ranging from 2 to 4. The entire length of these four segments was in good condition throughout. Also several areas of these pipe segments contained 5%‐50% sags. In summary, the average condition of the pipes in this area was good.

Table 1-26: Forest Avenue Sanitary Sewer

| Historic ID | - | Section ID | Description | - | - | - | - | - | |

|---|---|---|---|---|---|---|---|---|---|

| 1 | Start Location | End Location | Pipe Segment Reference | Broken, Cracks, Fracture, and Joint offset (Distance from Start) | Blockage (%) | Grease (%) | Sags (%) | Fine Roots | Condition |

| 115 | MH216 | MH215 | HU‐111 | Tap Factory‐ 97.8, 185.4, 257.1 | 5 | Good | |||

| 116 | MH215 | MH214 | HU‐110 | Tap Factory‐ 96.3, 133.4, 240.6 | 5 | Good | |||

| 117 | MH214 | MH213 | HU‐109 | Hinge Fracture 7.3 Tap Saddle‐ 115.7 | 5 | Good | |||

| 118 | MH213 | MH212 | HU‐108 | Tap Saddle‐ 71.2 | 5‐ 50 | Good | |||

3.9.3.5 Olive Street

Five sanitary sewer pipe segments were inspected at Olive Street. They ranged in condition from good to excellent. The segment of pipe between FI1 and MH223, and between FI2 and MH223, and between FI3 and MH225, and between FI and MH219, and between FI and MH219A are in excellent condition. The entire length of these five segments was in excellent condition throughout. In summary, the average condition of the pipes in this area was good.

Table 1-27: Olive Avenue Sanitary Sewer

| Historic ID | - | Section ID | Description | - | - | - | - | - | |

|---|---|---|---|---|---|---|---|---|---|

| 1 | Start Location | End Location | Pipe Segment Reference | Broken, Cracks, Fracture, and Joint offset (Distance from Start) | Blockage (%) | Grease (%) | Sags (%) | Fine Roots | Condition |

| 119 | FI1 | MH223 | LU‐222 | Excellent | |||||

| 120 | FI2 | MH223 | LU‐223 | Excellent | |||||

| 121 | FI3 | MH225 | LU‐225 | Excellent | |||||

| 122 | FI | MH219 | HU‐105B | Good | |||||

| 123 | FI | MH219A | HU‐106A | Good | |||||

3.9.3.6 Scott Street

Eleven sanitary sewer pipe segments were inspected at Scott Street. They ranged in condition from poor to fair. The segment of pipe between FI and MH133, and between MH133 and MH129, and between MH129 and MH303, and between MH303 and 125, and between MH125 and MH115 and between MH118 and MH108, and between MH108 and MH117, and between MH117 and 109, and between MH109 and MH112 and between MH112 and MH116, and between MH116 and MH115 consisted several locations of pipe in poor condition which contained broken soil visible, crack and fracture circumferential , crack and fracture longitudinal, crack and fracture multiple, hinge and spiral crack, joint offset and tap factory defective with a defect ranging from 1 to 5. The pipe in fair condition was on the verge of qualifying as being in poor condition because of it contained cracks and fracture circumferential at multiple locations throughout the pipe. Also several areas of these pipe segments contained 5%‐10% sags and fine roots. In summary, the average condition of the pipes in this area was poor.

Table 1-28: Scott Street Sanitary Sewer

| Historic ID | - | Section ID | Description | - | - | - | - | - | |

|---|---|---|---|---|---|---|---|---|---|