SEWER SYSTEM MANAGEMENT PLAN (SSMP) BURBANK SANITARY DISTRICT OF SANTA CLARA COUNTY

PREPARED BY:

MARK THOMAS

20863 Stevens Creek Boulevard, Suite 100 Cupertino, California 95014

(408) 255-2137

Certified: May 19, 2021

TABLE OF CONTENTS

EXECUTIVE SUMMARY 3

DOCUMENT VERSION CONTROL 4

INTRODUCTION 5

ELEMENT 1 – GOALS 11

ELEMENT 2 – ORGANIZATION 13

ELEMENT 3 – LEGAL AUTHORITY 16

ELEMENT 4 – OPERATIONS AND MAINTENANCE 18

ELEMENT 5 – DESIGN AND PERFORMANCE STANDARDS 37

ELEMENT 6 – OVERFLOW AND EMERGENCY RESPONSE PLAN 40

ELEMENT 7 – FATS, OILS, AND GREASE (FOG) CONTROL PROGRAM 57

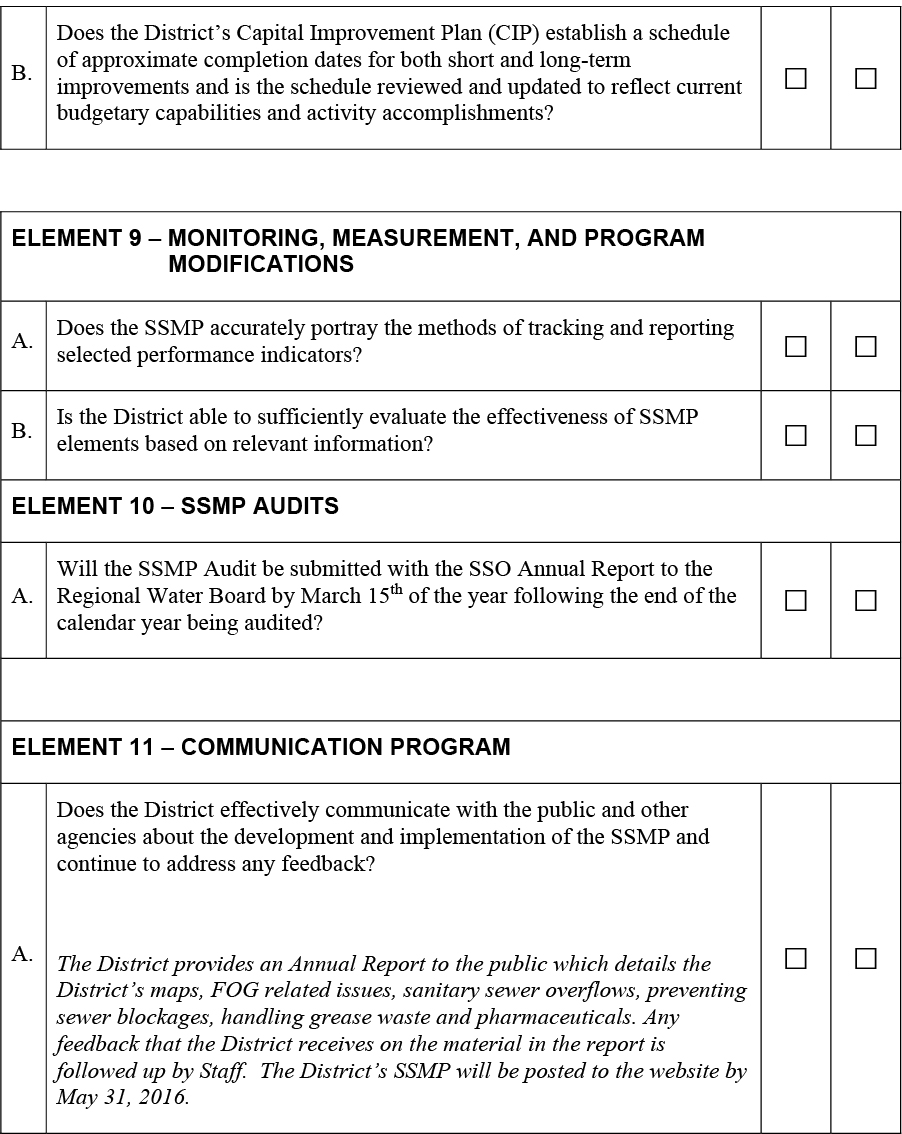

ELEMENT 8 – SYSTEM EVALUATION AND CAPACITY ASSURANCE PLAN 60

ELEMENT 9 – MONITORING, MEASUREMENT, AND PROGRAM MODIFICATIONS 62

ELEMENT 10 – SSMP AUDITS 65

ELEMENT 11 – COMMUNICATION PROGRAM 71

EXECUTIVE SUMMARY

This Sewer System Management Plan (SSMP) has been prepared in compliance with the State Water Resources Control Board (SWRCB) Order 2006-0003: Statewide General Waste Discharge Requirements for Sanitary Sewer Systems (GWDR), as revised by Order No. WQ 2008- 0002.EXEC on February 20, 2008. The GWDR prohibits sanitary sewer overflows (SSOs), requires reporting of SSOs using the statewide electronic reporting system, and requires the preparation of an SSMP.

The SWRCB has been working the past few years to develop a new State Waste Discharge Requirements (WDR) document and an administrative draft has been provided to stakeholders for review and comment. The current version of the draft document calls for changes to the format and content for Sewer System Management Plans. The new WDR will go through a review process through the summer and fall of 2021 and revisions to the draft language will be used to produce a new final WDR near the end of 2021.

The last SSMP for Burbank Sanitary District (BSD) was certified in May of 2016. The District is required to prepare and certify a revised SSMP every 5 years. As a result, this SSMP will be produced and certified in May of 2021 based upon the requirements of the Statewide GWDR as revised by Order No. WQ 2008-0002.EXEC on February 20, 2008.

Burbank Sanitary District (BSD) has implemented a sewer main condition assessment program which consists of CCTV inspection of the District mainlines within the District boundary. The inspection is used to forecast the overall condition of the sanitary sewer system and to identify the level of effort and budget required to maintain and improve the sanitary sewer system. The goal of this program is to identify the mains with the future capital improvement needs and to prioritize sewer mains for replacement or rehabilitation based on the NASSCO PACP overall pipe rating and defect scores.

In December of 2016 the District applied for a Clean Water State Revolving Fund (CWSRF) loan. On April 29, 2021 the District was notified that the CWSRF loan had been approved. The loan will provide funding for construction costs and soft costs (engineering, administration, and construction support) for the BSD District-wide Capitol Improvement Project. The work will be completed prior to August 2022.

DOCUMENT VERSION CONTROL

This Sewer System Management Plan (SSMP) is a living document that is anticipated to change over time. This version control sheet is intended to support Burbank Sanitary District’s efforts to keep the copies of the SSMP that have been assigned to District Staff current. Please contact Benjamin Porter prior to making copies for use by others, initiating changes, or for information regarding the current version of this document.

| wdt_ID | SSMP Section | Last Certified Date | Previous Version Date | Current Version Date |

|---|---|---|---|---|

| 1 | Introduction | |||

| 2 | 1. Goals | May 2016 | January 2018 | May 2021 |

| 3 | 2. Organization | May 2016 | May 2020 | May 2021 |

| 4 | 3. Legal Authority | May 2016 | January 2018 | May 2021 |

| 5 | 4. O&M Program | May 2016 | January 2018 | May 2021 |

| 6 | 5. Design and Performance Provisions | May 2016 | January 2018 | May 2021 |

| 7 | 6. Overflow Emergency Response Plan | May 2016 | May 2020 | May 2021 |

| 8 | 7. FOG Control Plan | May 2016 | January 2018 | May 2021 |

| 9 | 8. System Evaluation and Capacity Assurance Plan | May 2016 | January 2018 | May 2021 |

| 10 | 9. Monitoring, Measurement, and Program Modifications | May 2016 | January 2018 | May 2021 |

INTRODUCTION

This Sewer System Management Plan (SSMP) has been prepared in compliance with the State Water Resources Control Board (SWRCB) Order 2006-0003: Statewide General Waste Discharge Requirements for Sanitary Sewer Systems (GWDR), as revised by Order No. WQ 2008- 0002.EXEC on February 20, 2008. The GWDR prohibits sanitary sewer overflows (SSOs), requires reporting of SSOs using the statewide electronic reporting system, and requires the preparation of an SSMP.

This document has been prepared with the awareness that the District is one of a number of stakeholder agencies within a local watershed area of Santa Clara County each accountable by permit to the State Water Resources Control Board under the Clean Water Act. These stakeholders include:

- San Jose/Santa Clara Regional Wastewater Facility, Department of Environmental Services

- Santa Clara Valley Water District

- Santa Clara County Roads and Airports and Public Works Departments

Other stakeholders include the Santa Clara County Environmental Services Department and several privately organized environmental groups.

This SSMP includes the elements required by both the SWRCB and RWQCB and is organized following the SWRCB outline. Both SWRCB and RWQCB requirements are addressed in each element. Each requirement is shown as stated in the SSO-WDR and the RWQCB SSMP Development Guide.

BACKGROUND INFORMATION

BSD was established in 1940 to acquire, build, operate, and maintain a wastewater disposal system and provide solid waste collection services within an unincorporated area of Santa Clara County. The principal act that governs the District is the Sanitary District Act of 1923. The principal act empowers the District to acquire, plan, construct, reconstruct, alter, enlarge, lay, renew, replace, maintain, and operate all of the following: garbage dumpsites, garbage collection and disposal systems; sewers, drains, septic tanks, sewage collection, outfall, treatment works and other sanitary disposal systems; storm water drains, collection, outfall and disposal systems; and water recycling and distribution systems. BSD boundaries consist of two non-contiguous unincorporated areas that

are surrounded by the City of San Jose and within San Jose’s Urban Service Area (USA). The District’s boundaries currently encompass 0.28 square miles.

REQUIRED ELEMENTS OF AN SSMP

In summary, the required elements of an SSMP include:

- Collection System Management Goals

- Organization of Personnel, including Chain of Command and Communication

- Overflow Emergency Response Plan

- Fats, Oils and Grease Control Plan

- Legal Authority for permitting flows in the system, inflow/infiltration control as well as enforcement of proper design, installation, testing standards and inspection requirements for new and rehabilitated sewers

- Measures and activities to maintain the wastewater collection system

- Design and Construction Standards

- Capacity Management

- Monitoring, Measurement and Program Modifications

- Periodic SSMP audits and implementation of program improvements

- Communication Programs

DEFINITIONS, ACRONYMS, AND ABBREVIATIONS

Best Management Practices (BMP) – Refers to the procedures employed in commercial kitchens to minimize the quantity of grease that is discharged to the sanitary sewer system. Examples include scraping food scraps into the garbage can and dry wiping dishes and utensils prior to washing

Burbank Sanitary District (BSD) – Refers to special sanitary district established under the Sanitary District Act of 1923.

California Office of Emergency Services (Cal OES) – Refers to the agency responsible for overseeing and coordinating emergency preparedness, response, recovery and homeland security activities within the state. The agency was created in 2008, superseding both the Office of Emergency Services (OES) and Office of Homeland Security (OHS).

Calendar Year (CY) – January 1 to December 31.

California Department of Fish and Wildlife (CDFW) – Refers to the State agency responsible for overseeing fish and wildlife protection and services in the State of California.

California Integrated Water Quality System (CIWQS) – Refers to the State Water Resources Control Board online electronic reporting system that is used to report SSOs, certify completion of the SSMP, and provide information on the sanitary sewer system.

California Association of Sanitation Agencies (CASA) – Refers to an association of local agencies engaged in advancing the wastewater disposal system/technology and the recycling of wastewater into usable water, generation of renewable energy, and other valuable resources.

California Water Environmental Association (CWEA) – Refers to an association of local agencies engaged in protecting waters of United States.

Capital Improvement Program (CIP) – Refers to the document that identifies planned capital improvements to the District’s sanitary sewer system.

Certification of SSO Reports – The SWRCB requires the Legally Responsible Official (LRO, defined below) to log in to CIWQS within a given time period to electronically sign submitted reports thereby stating that to the best of his/her knowledge and belief, the information submitted is true, accurate, and complete.

Closed Circuit Television (CCTV) – Refers to the process and equipment used to inspect internally the condition of gravity sewers.

County Health – Refers to the Santa Clara County Public Health Department.

Environmental Protection Agency (U.S. EPA) – Refers to the United States Environmental Protection Agency.

Fats, Oils, and Grease (FOG) – Refers to fats, oils, and grease typically associated with food preparation and cooking activities that can cause blockages in the sanitary sewer system.

First Responder – Refers to the District employee who provides the District’s initial response to a sewer system alarm, emergency, or other event.

Field Report – Refers to the Sanitary Sewer Overflow Report, a document used to provide the basis for entering an overflow report into CIWQS.

Fiscal Year (FY) – Refers to July 1 to June 30 of each year.

Gallons per Acre per Day (gpad) – Refers to measurement of volume per acre.

Gallons per Day (gpd) – Refers to measurement of volume per day.

Gallons per Minute (gpm) – Refers to measurement of volume per minute.

General Waste Discharge Requirements (GWDR) – Refers to the State Water Resources Control Board Order No. 2006-0003, Statewide General Waste Discharge Requirements for Sanitary Sewer Systems, dated May 2, 2006, as revised on February 20, 2008.

Global Positioning System (GPS) – Refers to the handheld unit used to determine the longitude and latitude of sanitary sewer overflows for use in meeting the CIWQS Online SSO Reporting System reporting requirements. Google maps can be used in lieu of a GPS unit to obtain this information.

Grease Removal/Pretreatment Devices (GRD) – A Piece of equipment connected to the sewer line close to the source of FOG (fats, oils, and grease) being discharged. It is made up of a baffle system inside intended to slow the discharge long enough for the FOG to separate from the gray water (retention time). The FOG floats to the top of the reservoir inside the device, gray water flows through the sewer system and food particles drop to the bottom of the reservoir.

House Connection Sewer (Upper Lateral) – Refers to that portion of the horizontal sewer piping from the building or structure to the property line of the public right of way or easement.

Infiltration/Inflow (I/I) – Refers to water that enters the sanitary sewer system from storm water and groundwater that increases the quantity of flow. Infiltration enters through defects in the sanitary sewer system after flowing through the soil. Inflow enters the sanitary sewer system without flowing through the soil. Typical points of inflow are holes in manhole lids and direct connections to the sanitary sewer (e.g., storm drains, area drains, and roof leaders).

Legally Responsible Official (LRO) – Refers to the individual who has the authority to certify reports and other actions that are submitted through the Online SSO Reporting System.

Manhole (MH) – Refers to an engineered structure that is intended to provide access to a sanitary sewer for maintenance and inspection.

Millions of Gallons per Day (MGD) – Refers to measurement of volume in million gallons per day.

Monitoring, Measurement, and Program Modification (MMPM) – Refers to methods used in field for sewer overflows.

National Pollutant Discharge Elimination System (NPDES) – Refers to State of California permit for point and non-point source discharges.

Not Applicable (NA) – Refers to abbreviation used (NA) when something does not apply.

Notification of a SSO – Refers to the time at which the District becomes aware of a SSO event through observation or notification from the public or other source.

Office of Emergency Services (OES) – See California Emergency Management Agency.

Online SSO Reporting System – Refers to the California Integrated Water Quality System (CIWQS).

Operations and Maintenance (O&M) – Refers generally to annual operations and maintenance activities of the sanitary sewer system.

Overflow Emergency Response Plan (OERP) – Refers to established plan of the District in response to an emergency.

Preventive Maintenance (PM) – Refers to the maintenance activities intended to prevent failures of the sanitary sewer system facilities (e.g., cleaning, CCTV, inspections).

Private Lateral Sewage Discharges – Sewage discharges that are caused by blockages or other problems within a privately owned sewer service lateral.

Property Damage Overflow – Property damage overflow refers to a sewer overflow or backup that damages private property.

Public Sewer – As stated in the District Operations Code, this refers to any mainline sewer constructed in any street, highway, alley, place or right of way dedicated for public use.

Regional Water Board – Refers to the San Francisco Bay Regional Water Quality Control Board – Region 2.

Regional Water Quality Control Board (RWQCB) – Refers to the San Francisco Bay Regional Water Quality Control Board – Region 2 and Regional Water Board.

Sanitary Sewer Overflow (SSO) – Any overflow, spill, release, discharge or diversion of untreated or partially treated wastewater from a sanitary sewer system. SSOs include:

- Overflows or release of untreated or partially treated wastewater that reach waters of the United States; and

- Overflows or release of untreated or partially treated wastewater that do not reach waters of the United States; and

- Wastewater backups into buildings and on private property that are caused by blockages or flow conditions within the publicly owned portion of a sanitary sewer system.

Sanitary Sewer System – Refers to the portion of the sanitary sewer facilities that are owned and operated by Burbank Sanitary District. The sanitary sewer system consists of collection sewers and trunk sewers

Sensitive Area – Refers to areas where a SSO could result in a fish kill or pose an imminent or substantial danger to human health (e.g., parks, aquatic habitats, etc.).

Sewer Service Lateral – For the purposes of this SSMP, the sewer service lateral includes both the upper lateral (house connection sewer) and the lower lateral (sewer lateral).

Sewer Lateral (Lower Lateral) – Refers to the portion of the pipe from upper lateral (house connection sewer) to the sewer main, including the connection to the sewer main. The property owner is responsible for repairing any failure or damage in the upper sewer lateral. District is responsible for repairs, including the connection to the sewer main; unless it is determined that another party caused the failure or damage of the sewer lateral (Lower Lateral).

Sewer System Management Plan (SSMP) – Refers to State mandated program for sewer management

Santa Clara County Public Health Department (County Health) – Refers to Santa Clara County Health Department.

Standard Operating Procedures (SOP) – Refers to written procedures that pertain to specific activities employed in the operation and maintenance of the sanitary sewer system.

State Water Resource Control Board (SWRCB) – Refers to the California Environmental Protection Agency (Cal/EPA) State Water Resources Control Board and staff responsible for protecting the State’s water resources.

Surface Waters – See waters of the State

System Evaluation and Capacity Assurance Plan (SECAP) – Refers to methods employed to assure adequate available capacity.

Trunk Sewer or Main Interceptor System – The terms trunk sewer, gravity trunk line, and main interceptor sewer are used interchangeably to refer to the main branches of the sanitary sewer system that carry flows from the collector sewers to the treatment plant.

Volume Captured – The amount of spilled sewage that is returned to the sanitary sewer system. When recording the volume that is captured, the volume of water used for flushing and/or cleaning should not be included.

Water Body – A water body is any stream, creek, river, pond, impoundment, lagoon, wetland, or bay.

Waters of the State – Waters of the State means any water, surface or underground, including saline waters, within the boundaries of California. In case of a sewage spill, storm drains are considered to be waters of the State unless the sewage is completely contained and returned to the sanitary sewer system and that portion of the storm drain is cleaned.

Work Order (WO) – Refers to the document (paper or electronic) that is used to assign work and to record the results of the completed work.

ELEMENT 1 – GOALS

SWRCB Requirements:

The goal of the Sewer System Management Plan (SSMP) is to provide a plan and schedule to properly manage, operate, and maintain all parts of the sanitary sewer system. This will help reduce and prevent SSOs, as well as mitigate any SSOs that do occur.

RWQCB Requirements:

Each wastewater collection system agency shall, at a minimum, develop goals for the Sewer System Management Plan as follows:

- To properly manage, operate, and maintain all parts of the wastewater collection system

- To provide adequate capacity to convey peak flows

- To minimize the frequency of SSOs

- To mitigate the impact of SSOs

The purpose of the SSMP is to provide guidance to the District in the operation, management and maintenance of its sewer collection system in order to comply with the SWRCB Order No. 2006-003 DWQ and RWQCB requirements outlined in the Sewer System Management Plan Development Guide. The District is charged with collecting sewage waste within its service boundaries and conveying it to the San Jose/Santa Clara Water Pollution Control Plant. The District’s goal is to carry out maintenance and operation of the sewer collection system with no adverse impact to the public health or environment.

The provisions of the SSMP were developed and updated to ensure that the District can meet its goals by:

- Implementing a collection system maintenance program to minimize the frequency of sanitary sewer overflows.

- Responding to sanitary sewer overflows quickly and mitigating the impact of the SSO.

- Mitigating the impact of sewer overflows that do occur as well as follow up investigations to identify the cause of the overflow event and using that information to either adjust the maintenance schedule or schedule a repair/replacement.

- Properly managing, operating, and maintaining all elements of the wastewater collection system to better allocate resources and manpower.

- Cost effectively minimizing infiltration/inflow (I/I) and analyzing the existing capacity and developing a plan to provide adequate capacity for future development and to convey peak dry weather flows.

- Developing and maintaining design construction standards and specifications for the

installation and repair of the collection system and its associated infrastructure.

• Maintaining comprehensive and up-to-date maps of the wastewater collection system.

• Coordinating with the City of San Jose and Santa Clara County to maintain storm water maps.

• Providing training on a regular basis for staff in collection system maintenance and operations.

• Encouraging and supporting participation in the quarterly meetings with the neighboring

collection system agencies and the partners to the wastewater treatment plant.

• Maintaining Fats, Oils, and Grease (FOG) program to limit fats, oils, and grease, and other

debris that may cause blockages in the sewage collection system.

• Developing a closed-circuit televising (CCTV) program for the collection system.

The District has implemented policies and procedures for the systematic inspection and continued maintenance of its infrastructure and engages contracted, competent, trained personnel to carry out the scheduled tasks. The District personnel and contractors are utilizing the procedural training available through organizations such as California Association of Sanitation Agencies (CASA) and California Water Environment Association (CWEA).

ELEMENT 2 – ORGANIZATION

SWRCB Requirements:

The Sewer System Management Plan (SSMP) must identify:

a. The name of the responsible or authorized representative as described in Section J of this

order

b. The names and telephone numbers for management, administrative, and maintenance positions responsible for implementing specific measures in the SSMP program. The SSMP must identify lines of authority through an organization chart or similar document with a narrative explanation; and

c. The chain of communication for reporting SSOs, from receipt of a complaint or other information, including the person responsible for reporting SSOs to the Health and Regional Water Board and other agencies if applicable (such as County Health Officer, County Environmental Health Agency, Regional Water Board, and/or Cal EMA).

RWQCB Requirements:

Each wastewater collection system agency shall, at a minimum, provide the following information regarding organization:

- Identify agency staff responsible for implementing, managing, and updating the SSMP

- Identify chain of communication for responding to SSOs

- Identify chain of communication for reporting SSOs

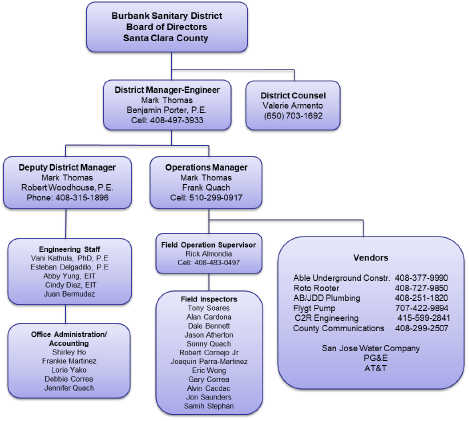

The District Organization Chart is provided below in Figure 1 and indicates the chain of responsibility for the management, operation and maintenance of the District’s collection system. District contracts its management, engineering and operation with Mark Thomas and Company Inc.

The RWQCB requires certification by LRO. District policy is to have one LRO review and determine that the SSMP is “ready for certification”. The second LRO then certifies the SSMP. The persons responsible are:

Benjamin Porter, District Manager-Engineer (408) 497-3933

Robert Woodhouse, Deputy District Manager (408) 477-7320

Frank Quach, Operations Manager/Project Manager (510) 299-0917

Chain of Communication for Reporting SSOs

- Burbank Sanitary District (408) 255-2137; after business hours/holidays (408) 299-2507 receives call of SSO from the public or other agency.

- First Responder dispatched to spill site requests. Response Crew to meet at scene

- SSO report form completed by First Responder with GPS Coordinates to define location.

- Category 1 spill: one of the above staff will be at the site

- SSO form forwarded to Benjamin Porter or Robert Woodhouse

- Frank Quach or designee inputs SSO into statewide SSO database via CIWQS website.

- Robert Woodhouse or Benjamin Porter make SSO Report “ready to certify”

- Robert Woodhouse or Benjamin Porter certify the SSO Report.

Authorized Representative

The District’s Authorized Representatives in all sanitary sewer system matters are Benjamin Porter (District Manager-Engineer), Robert Woodhouse (Deputy District Manager) and Frank Quach (Operations Manager). Porter, Woodhouse and Quach are authorized to submit verbal, electronic, and written spill reports to the RWQCB, SWRCB, County Health, and Cal OES. Benjamin Porter and Robert Woodhouse are the District’s designated Legally Responsible Officials (LROs) and are authorized to certify electronic spill reports submitted to the SWRCB.

Responsibility for SSMP Implementation

Robert Woodhouse is responsible for developing, implementing, and maintaining all elements of the District’s SSMP

DISTRICT ORGANIZATION

ELEMENT 3 – LEGAL AUTHORITY

SWRCB Requirements:

Each enrollee must demonstrate, through sanitary sewer system use ordinances, service agreements, or other legally binding procedures, that it possesses the necessary legal authority to:

a. Prevent illicit discharges into its sanitary sewer system (examples may include I/I, storm water, chemical dumping, unauthorized debris and cut roots, etc.); and

b. Require that sewers and connections be properly designed and constructed; and

c. Ensure access for maintenance, inspection, or repairs for portions of the lateral owned or maintained by the Public Agency; and

d. Limit the discharge of fats, oils, and grease and other debris that may cause blockages; and

e. Enforce any violation of its sewer ordinances.

RWQCB Requirements:

Each wastewater collection system agency shall, at a minimum, describe its legal authority through sewer use ordinances, service agreements, or other legally binding procedures to:

• Control infiltration/inflow (I/I) from satellite wastewater collection systems and laterals.

• Require proper design and construction of new and rehabilitated sewers and connections.

• Require proper installation, testing, and inspection of new and rehabilitated sewers.

The powers of and the execution of Legal Authority provided by and through the governing body of the Burbank Sanitary District (District) and directed by the District Manager-Engineer, for sewer use, services, construction, permits and procedures are applicable to all industrial, business or residential entities and are cited in the District Ordinance No. 4, dated September 1941 and Ordinance No. 5, dated May 9, 1942 and as amended.

The District hereby declares that the following procedures are established as a means of enforcement of the terms and conditions of this Code or any other ordinances, rules and regulations, and not as a penalty. The Government Code of the State of California, Health and Safety Code of the State of California, Code of Federal Regulations, City Health Department, County Health Department, Environmental Protection Agency, Civil Code of the State of California, County of Santa Clara, NPDES, Plumbing and Electrical Codes are referenced within the District’s Operations Code.

The primary responsibility for enforcement of the provisions of this Code is vested in the District Manager-Engineer or District agents as designated, field inspectors or other representatives of the District and the San Jose/Santa Clara Water Pollution Control Plant authorized to act on behalf of the District Manager-Engineer, having the power to inspect and issue notices for violations.

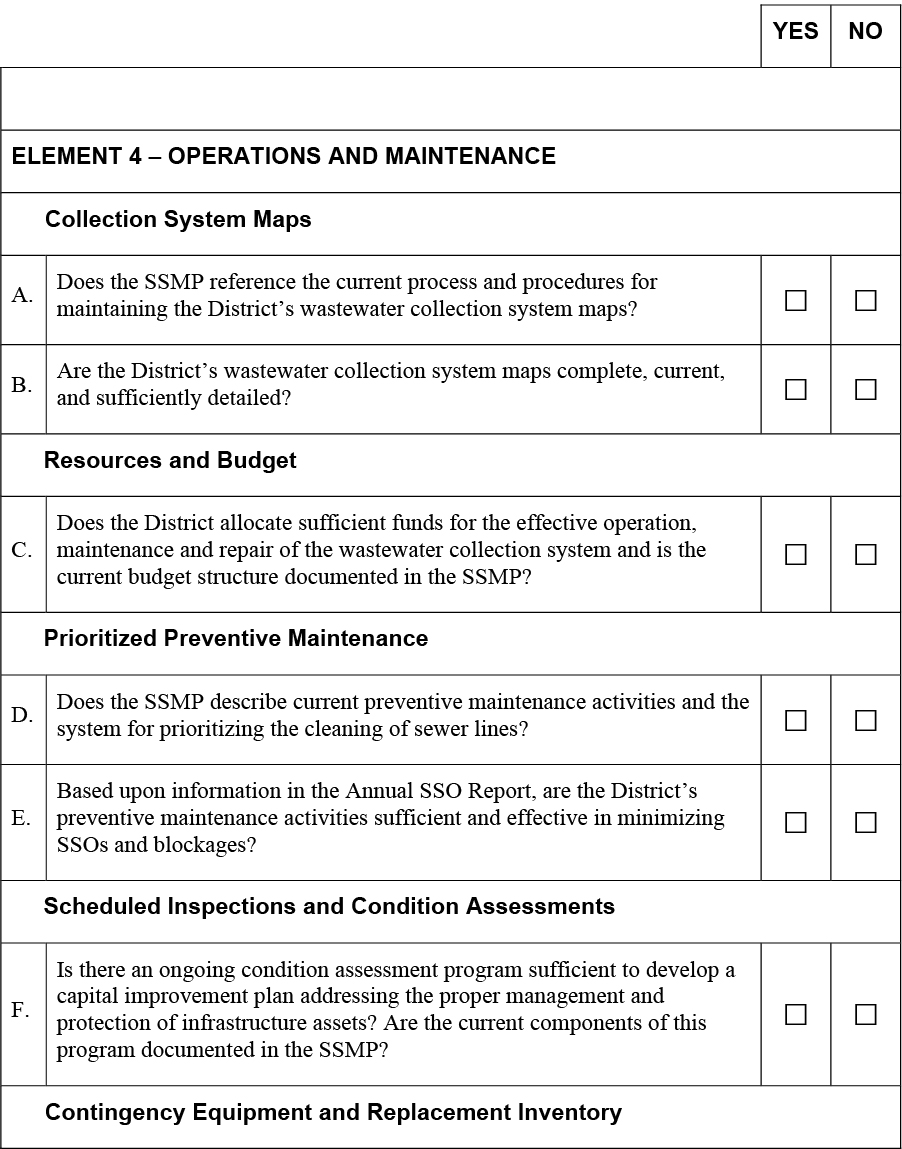

ELEMENT 4 – OPERATIONS AND MAINTENANCE

SWRCB Requirements:

The Sewer System Management Plan (SSMP) must include those elements listed below that are appropriate and applicable to the enrollee’s system:

a. Maintain an up-to-date map of the sanitary sewer system, showing all gravity line segments and manholes, pumping facilities, pressure pipes, and applicable stormwater conveyance facilities; and

b. Describe routine preventive operation and maintenance activities by staff and contractors, including a system for scheduling regular maintenance and cleaning of sanitary sewer system with more frequent cleaning and maintenance targeted at known problem areas. The Preventive Maintenance (PM) program should have a system to document scheduled and conducted activities, such as work orders; and

c. Develop a rehabilitation and replacement plan to identify and prioritize system deficiencies and implement short-term and long-term rehabilitation actions to address each deficiency. The program should include regular visual and TV inspections of manholes and sewer pipes, and a system of ranking the condition of the sewer pipes and scheduling rehabilitation. Rehabilitation and replacement should focus on sewer pipes that are at risk of collapse or prone to more frequent blockages due to pipe defects. Finally, the rehabilitation and replacements plan should include a capital improvement plan that addresses proper management and protection of the infrastructure assets. The plan shall include a time schedule for implementing the short- and long-term plans plus a schedule for developing the funds needed for the capital improvement plan; and

d. Provide training on a regular basis for staff in sanitary sewer system operations and maintenance, and require contractors to be appropriately trained; and

e. Provide equipment and replacement part inventories, including identification of critical replacement parts.

RWQCB Requirements:

Collection System Map – Each wastewater collection system agency shall maintain up-to-date maps of its wastewater collection system facilities.

Resources and Budget – Each wastewater collection system agency shall allocate adequate resources for the operation, maintenance, and repair of its collection system

Prioritized Preventive Maintenance – Each wastewater collection system agency shall prioritize its preventive maintenance activities

Scheduled Inspections and Condition Assessment – Each wastewater collection system agency shall identify and prioritize structural deficiencies and implement a program of prioritized shortterm and long-term actions to address them.

Contingency Equipment and Replacement Inventories – Each wastewater collection system agency shall provide contingency equipment to handle emergencies, and spare/replacement parts intended to minimize equipment/facility downtime.

Training – Each wastewater collection system agency shall provide training on a regular basis for its staff in collection system operations, maintenance, and monitoring

Outreach to Plumbers and Building Contractors – Implement an outreach program to educate commercial entities involved in sewer construction or maintenance about the proper practices for preventing blockages in private laterals. This requirement can be met by participating in a regionwide outreach program

Operations and Maintenance Activities

The District’s sewage flows are collected by the District’s nearly 8 miles of service laterals and mains and then transmitted through joint use mains, interceptors and trunk lines by contractual agreement with the City of San Jose to the San Jose-Santa Clara Regional Wastewater Facility for treatment and disposal.

Costs of wastewater treatment and disposal are based upon the terms of a Master Agreement between the Cities of San Jose and Santa Clara, owners of the San Jose-Santa Clara Regional Wastewater Facility, and Burbank Sanitary District, dated May 1, 1985. The Master Agreement provides for treatment capacity right and appropriate allocation of capital, operations, and maintenance costs.

The District’s management is provided by contractual agreement with Mark Thomas & Company Inc., a private consultant responsible for day-to-day administration and oversight of the District’s facilities and operations. Repairs and maintenance activities are provided as scheduled or needed with outside contractors and overseen by Mark Thomas and Company field inspection personnel.

Outside Contractors providing routine maintenance and emergency response services are required by the District’s Operations Code to be registered annually with the District providing evidence of current insurance coverage in force at the limits set forth by the District. In addition, contractor is required to comply with the current prevailing wage requirements and to be in compliance with the Department of Industrial Relations.

The contractors must also demonstrate professionalism and competency to carry out the assigned tasks of maintenance and repairs of the District’s facilities. A contractor’s safety record is considered as well as observed safe practices and well-established workmanlike performance.

Maintenance activities are overseen by District inspection staff and findings of existing condition of sewer mains are logged and evaluated on a priority of needed attention or repair. Attention can range from increased frequency of cleaning to video inspection to determine extent of needed spot repairs or eventual replacement of a significant section of sewer main. Mains found to be significantly in disrepair or undersized are placed on a prioritized list on the District’s Capital Improvement Program to be rehabilitated by pipe-bursting or replacement to increase capacity, eliminate sources of I & I and/or improve integrity of the system.

The major elements of the District’s Operation and Maintenance Program are:

1. Collection System Mapping

2. Description of Existing Facilities

3. Sewer Maintenance Management System

4. Annual Routine Maintenance

5. Rehabilitation and Replacement Plan

6. Capital Improvement Program

7. Staff Training and Certification

8. Maintenance Equipment

Collection System Maps and Description of Existing Facilities

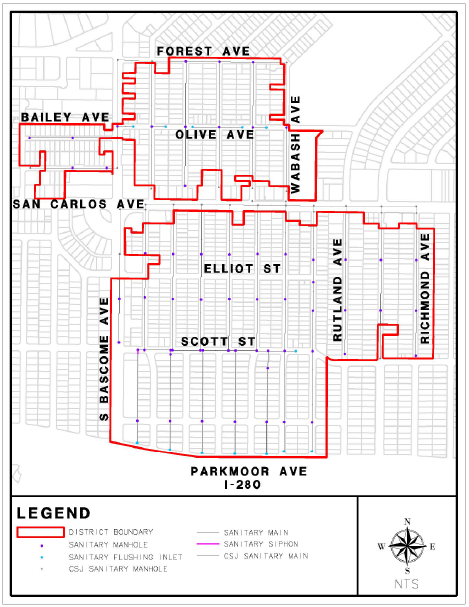

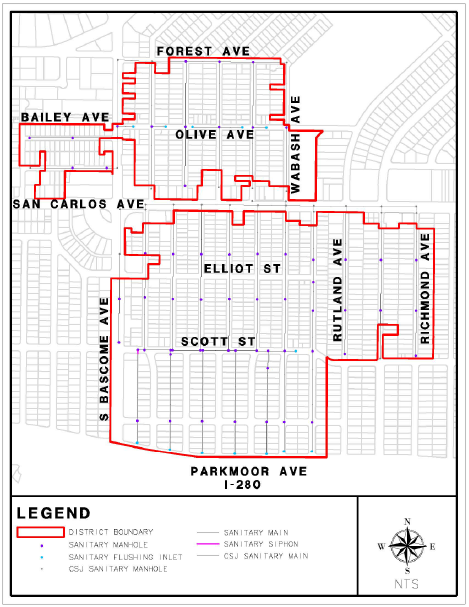

The District provides wastewater collection services to an area composed mostly residential single-family homes. Most of the commercial and institutional zones have been annexed by the City of San Jose. The district has gravity mains located on the streets and easements. Only about 13% of the Districts gravity mains are in easement. Figure 2 shows a map of the District service area boundary and exiting facilities.

DESCRIPTION OF EXISTING FACILITIES

The District Maintains approximately 5.56 miles of sewer mains. Since the District is relatively small compared to the neighboring wastewater collection system, the District only maintains and operates gravity mains. The collected wastewater is conveyed to the San Jose/ Santa Clara Reginal Wastewater Facility via the City of San Jose Sewer System

Table 1 and Table 2 provide information about the District’s Collection System assets.

• Table 1 shows the breakdown of sewer gravity mains by pipe diameter. The distribution of size, amount of length in feet and miles is shown in the table.

• Table 2 provides a count of the different sewer structures within the District.

The diameter of sewer mains ranges from 4 inches to 15 inches. The district operates and maintains 1,096 lower laterals. The collected wastewater is conveyed to the San Jose/ Santa Clara Reginal Wastewater Facility via the City of San Jose Sewer System.

Table 1: BSD Sewer Mains by Diameter and Length

| wdt_ID | Pipe Diameter (inches) | Length (Feet) | Length (Miles) | Length (Miles) |

|---|---|---|---|---|

| 1 | 15 | 100 | 0,02 | 0 |

| 2 | 10 | 961.1 | 0.18 | 3.3 |

| 3 | 8 | 2151.1 | 0.41 | 7.3 |

| 4 | 6 | 25727.5 | 4.87 | 87.7 |

| 5 | 4 | 396.5 | 0.08 | 1.4 |

| 6 | Total | 29336.2 | 5.56 | 100.0 |

Table 2: Sewer Assets

| wdt_ID | Sewer Structures | Total Count |

|---|---|---|

| 1 | Manhole | 60 |

| 2 | Flushing Inlet | 5 |

| 3 | Cleanout | 6 |

| 4 | Riser | 2 |

The District has map records in the following three formats:

a) Records of permitted, connected parcels are keyed to the County’s Assessor Maps which are utilized to show addresses and permit numbers issued. These are electronically retained and updated annually to keep current with ongoing record map changes within the District’s Service Area. The maps also include schematic diagrams of the District’s mains and service laterals with references for users to As-Built map sources.

b) Assessment diagrams for Local Improvement District projects and the associated As-built plans are maintained on file and available electronically as well. Maps of other District funded projects; federally funded Trunk Lines and the District’s outfall interceptor through the City of San Jose leading to the San Jose/Santa Clara WPCP are also maintained at the service counter and are accessible electronically as well. Subdivision Maps and associated developer installed As-built plans are maintained as the balance of the District’s infrastructure construction history and are also available electronically.

c) The District also maintains 100 scale maps that show the total boundaries of the areas served and the related Service Area Boundaries established by LAFCO. The District’s 100 scale maps are ACAD generated and includes scale, north arrow, date of last version, service area boundaries, property lines, manholes and other access points, street names, main, trunk, easement lines and dimensions, pipe ID’s, pipe diameter, and flow direction. Sanitary sewer laterals are not included in the maps due to visibility issue.

The City of San Jose has provided their storm sewer base map for the areas adjacent to the District

boundaries. The storm sewer base map from the County of Santa Clara has not been made available

to the District.

Sewer Maintenance Management System

The District’s current database is maintained through daily logs and spreadsheets and is updated continually. Work orders are generated based on the database for maintenance operation; and scheduling is developed using the database information. The primary functions of the District’s database are:

• Maintain service request and maintenance history information for each individual collection system asset.

• Produce and regularly update the maintenance schedule based on feedback information from the cleaning operations.

• Generate reports that support data analysis and decision-making.

• Provide documentation for use in regulatory compliance reporting.

• Indicate line segment or structures that may be candidates for replacement or rehabilitation under the capital improvement program.

GraniteNet database: The District is currently in the process of implementing the GraniteNet database for all future Capital Planning. All Pipeline scores can also be made visible with the optional ESRI Interface Module present in the GraniteNet software. This software will assist engineering in determining which pipelines to repair or replace, and when. An example of the GraniteNet interface is shown in the Figure 3.

Routine Maintenance

The District’s routine maintenance includes scheduled and planned maintenance of the entire collection system on a 36-month cycle. The main goal of the routine maintenance is to ensure that the collection lines, manholes, and other sewer infrastructures are free of any obstacles.

Outside contractors provide routine maintenance and emergency response services as required by the District through a work order system. The contractors utilize hydroflush, VacCon, or continuous rodder to clean and maintain the District sewer mains. After each line cleaning, the District Inspector uses the work order to document the field activities. Upon completion of the daily field work, the District Inspector enters the information from the work orders into the database. Sewer laterals are being cleaned with rodders or a snake machine.

Annual Routine Maintenance Prioritization List

The annual maintenance program prioritization is based on the following factors of the sanitary sewer collection system:

A. Root Control

Established neighborhoods and pipe segments located within easements with a history of root intrusion are maintained with power rodding and high-pressure rodding cleaning. Pipeline assessment and history analysis will determine the frequency of the maintenance for these lines. The District conducts root treatment operations for pipe segments with medium and heavy roots. The District is scheduled to hydro-jet clean all root foam-treated lines approximately six to ten weeks after the treatment. The areas targeted for root foaming were identified based on data received from the past maintenance work recorded and CCTV inspection findings.

B. Grease Conditions

Sewers with a history of repeated calls for grease stoppages are maintained at a frequency that is intended to prevent repeat stoppages or SSOs. The District performs preventive maintenance of these lines and conducts an annual inspection of pines with a history of grease problems. The District works closely with the County of Santa Clara Environmental Health Department in the implementation of the Fats, Oils, and Grease (FOG) reduction program by educating food establishments on Best Management Practices.

Condition Assessment of BSD Sewer Mains

The District has implemented a sewer main condition assessment program which consists of CCTV inspection of the District mainline sewers within the District boundary. The inspection is used to forecast the overall condition of the sanitary sewer system and to identify the level of effort and budget required to maintain and improve the sanitary sewer system. The goal of this program is to identify the sewer mains with the future capital improvement needs and to prioritize sewer mains for replacement or rehabilitation based on the NASSCO PACP overall pipe rating and defect scores.

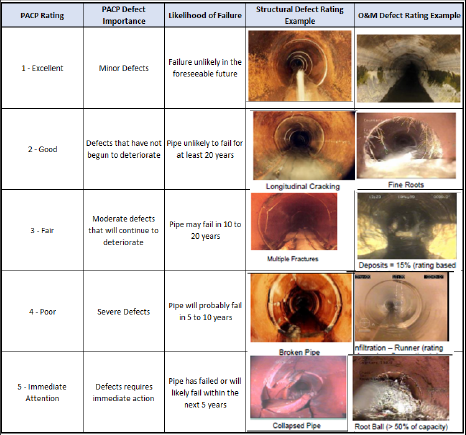

CCTV provides information about the condition of the pipes so they can be properly maintained, repaired, and/or replaced. CCTV inspections were completed using the nationally recognized method, which are Pipeline Assessment and Certification Program (PACP). PACP Version 7.0 was used in the assessment of the pipes.

The National Association of Sewer Service Companies (NASSCO), along with the assistance of the Water Research Centre (WRC), has developed a national certification program to establish a viable solution to standardize the identification, categorization, evaluation, and prioritization of sanitary sewer or storm sewer infrastructure through CCTV investigations

The PACP defect descriptions are organized into the following general categories:

• Structural Defect Coding: This group includes the type of defects where the pipe is considered to be damaged ranging from a minor case defect to a more severe case, depicted as pipe failure. The Structural Defect Coding group includes defects described as: cracks, fractures, broken pipe, holes, deformities, collapsed pipes, joint defects, surface damage defects, weld failures, point repair codes, brickwork defects, and lining failures.

• Operation and (O&M) Coding: This group includes the various codes that involve the spectrum of defects that may impede the operation and maintenance of the sewer piping system. The Operation and Maintenance Coding group includes defects comprised of roots, infiltration, deposits and encrustations, obstacles/obstructions, and vermin

• Construction Features Coding: This group includes the various codes associated with the typical construction of the sewer piping system. The Construction Features Coding group includes taps, intruding seal material, pipe alignment codes, and access points.

• Miscellaneous Features Coding: This group includes observation codes such as water levels (detection of sags), pipe material changes, and dye testing notes.

Condition ratings are allocated through visual inspection of the pipe using PACP defect types. Assigning a rating to each inspected pipe gives a measure of the level of physical deterioration with respect to the “as new” condition. In this investigation quick scores were utilized to understand the condition of a pipe. There is a separate quick score for Structural and O&M defects were used to rate the overall condition of the pipe.

The NASSCO quick rating system is a four-character number that displays the occurrences of defects for the two highest grades.

• The first character represents the highest severity grade defect that is observed along the pipe

• The second character represents the total number of occurrences for the highest severity grade.

• The third character represents the next highest severity grade observed through the pipe.

• The last character is the total number of occurrences of the second highest severity grade.

If the number of occurrences surpasses nine, the rating then uses letters as follows: A= 10 to 14, B= 15 to 19, and C = 20 to 24, etc. For example, the quick score 462B determined that there is six (6) grade 4 defects and fifteen (15) grade 2 defects. The quick score for each segment inspected will be found in the summary table for each basin.

PACP also provides a standardized system for the consistent assessment of sanitary sewer conditions. The two key concepts are the severity of the condition and the criticality of the defects was considered as part of the PACP grading system. The PACP rating process identifies the major deterioration factors and assigns a rating that is related to the likelihood of failure or collapse. Deterioration factors are classified into categories of structural, operation and maintenance defects. PACP utilizes condition rating (grading) system.

Each defect can be scored with a defect grade ranging from 1 to 5, where a grade 5 has the greatest potential for pipe failure, as described in Figure 4. The 1 to 5 grades based on the defect types are allocated directly by the CCTV inspector during the CCTV inspection process. The PACP Rating on a scale of 1 to 5 as shown in the Figure 8, summarizes the condition of a sewer length, generally from manhole to manhole. Example photos shown in Figure 4 are from Water Research Center (WRC) Rehabilitation Manual.

The assigned grades for each pipe segments are managed in the District’s GraniteNet, MS Access, PDF and in MS Excel so that inspection data and gradings are readily available to both engineering and maintenance staff. This condition information is used for making informed decisions on the amount and type of maintenance that may be required and for identifying when to rehabilitate sewers mains and the type of rehabilitation to be performed so that the performance and condition of the collection systems are maintained.

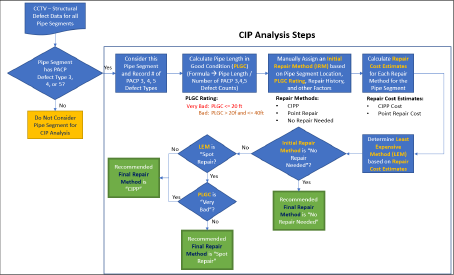

Condition Assessment and Rehabilitation Methodology for Sewer Mains

BSD has implemented a condition assessment and rehabilitation program to identify the mains with the future capital improvement needs and to prioritize sewer mains for replacement or rehabilitation based on the NASSCO’s PACP overall pipe rating and defect scores. The PACP rating process identifies the major deterioration factors and assigns a rating that is related to the likelihood of failure or collapse. Each pipe segment was scored with a defect grade ranging from 1 to 5, with highest ratings assigned to those defects that have the highest probability of failure. The pipe segments receiving an overall PACP score of 1 or 2 is not considered for BSD rehabilitation. The prioritization process emphasis was placed on pipe segments receiving an overall pipe score of 3, 4 or 5. These overall pipe scores indicate that these pipe segments have defects with severity levels of 3, 4 or 5. Pipe segments with pipe defect score of 3, 4 or 5 are further screened and the rehabilitation method is selected based on the Condition Assessment and Rehabilitation Methodology steps in the Figure 5.

The condition assessment and rehabilitation methodology have three final recommendations: no action required, Immediate action needed: point repair and Immediate action needed: cured-in place lining (CIP rehab). The recommended course of action for each sewer mains is based on the combination of extent of defect length, the percentage of pipe in good condition, and number of defects belonging to defect score of 3 or 4 or 5. As a part of step 1, an initial repair method is recommended based on the percentage of pipe remaining in good condition. If the percentage of pipe remaining in good condition is less than 20 ft, an initial recommendation method of CIP rehab is assigned to the main segment. If the percentage of pipe remaining in good condition is between 20 feet and 40 feet, an initial report method of point repair or CIP rehab is recommended. If the percentage of pipe remaining is more than 40 feet, then all three options are considered. As a part of Step 2, repair cost estimate calculation process is calculated for the projects that are identified as needing further point repair or CIP.

Re-prioritizing Based on the Least Cost Rehabilitation Method

In addition to the structural condition rating, BSD reprioritized the sewer mains based on the least expensive criteria. This approach is showed in the Figure 5, it provides the answer to questions like “Which sewers are costing the most to do point repair and which sewers may cost us most if a failure occurs and if they are not lined completely?”

The repair and rehabilitation costs were calculated for each sewer mains based on the initial sewer repair method. The unit cost to do cured-in place is ranged from $280/feet to $425/feet based on the diameters ranging from 4inches to 10 inches respectively; and point repair to be $7000/repair. Initial Repair Cost is calculated for all the pipe segments based their recommended method. Final recommendation is made based on the initial repair method and the least expensive method to repair the pipe segment.

Burbank Sewer Rehabilitation Capital Improvement Projects

In December of 2016, the District applied for a Clean Water State Revolving Fund (CWSRF) loan. On April 29, 2021, the District was notified that the CWSRF loan had been approved. The loan will provide funding for construction costs and soft costs (engineering, administration, and construction support). The funds from the CWSRF loan will be allocated towards the Districtwide Capitol Improvement Project. The work will be completed prior to August 2022. Table 3 provides a summary of the rehabilitation methods based on their condition for each project area

The CIP project will be conducted in two phases. Phase 1 involves the rehabilitation of sewer located within the Burbank street right of way. Priority will be placed on phase one as these mains provide wastewater collection to the majority of the District’s customers. Following the completion of phase 1, the District will continue the phase 2 rehabilitation work to repair pipes that are located in sewer easements. Figure 6 shows the location of where the rehabilitation work will take place

| wdt_ID | Rehabilitation Priority | Location | Segment | Description |

|---|---|---|---|---|

| 1 | 1 | Bailey Ave | LU-101 | 3 Spot Repairs |

| 2 | 1 | Bailey Ave | LU-102 | 5 Spot Repairs |

| 3 | 1 | Cecil St | LU-103 | CIPP |

| 4 | 1 | Cecil St | LU-104 | CIPP |

| 5 | 1 | Cecil St | LU-104A | CIPP |

| 6 | 1 | Bascom Ave | HU-101 | CIPP |

| 7 | 1 | Cleveland Ave | LU-107 | CIPP |

| 8 | 1 | Cleveland Ave | LU-107A | CIPP |

| 9 | 1 | Brookland Ave | LU-108 | CIPP |

| 10 | 1 | Brookland Ave | LU-108A | CIPP |

Safety Training and Certification

The District uses a combination of in-house classes, on-the job training, conferences and seminars, and other training opportunities to train its District Personnel. Staff regularly participates in technical seminars, conferences, and meetings with the following:

1. California Water Environment Association (CWEA)

2. Bay Area Clean Water Agencies (BACWA)

3. California Association of Sanitation Agencies (CASA)

All District Personnel are provided copies of the Standard Operating Procedures and trained on every piece of equipment assigned for the task including but not limited to:

1. SSO and Backup Response

2. Sewer Cleaning Equipment O&M

3. CCTV Operation and Maintenance

4. Lock Out/Tag Out

On-the job training is also received through mentoring by senior staff. Regular safety trainings are held to develop and maintain qualified staff.

The CWEA Technical Certification Program provides certification in a variety of wastewater disciplines to promote and enhance the education and effectiveness of the wastewater professional. The District encourages its maintenance staff to obtain CWEA certification to demonstrate their level of competency in collection system maintenance. By providing adequate staff training and establishment of certain grade level requirements as a condition of career advancement, the District reinforces the importance it places on certification

Table 4: District Staff

| wdt_ID | Staff Member | Title | Professional Engineer California | CWEA Certificati on | CCTV | Confined Space | Trench/ Excavation | Traffic Control | CPR/ First Aid/A ED | Water Sample Collection |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | Benjamin Porter, PE | District Manager/Engineer | Yes | |||||||

| 2 | Frank Quach, PE | Operations Manager | Yes | PACP, LACP, MACP | Yes | Yes | Yes, MUTCD | Yes | Yes | |

| 3 | Robert Woodhouse, PE | Deputy District Manager | Yes | |||||||

| 4 | Vani Kathula, PE | Senior Sanitary Engineer | Yes | PACP, LACP | Yes | |||||

| 5 | Esteban Delgadillo, PE | Design Engineer | Yes | Yes, MUTCD | ||||||

| 6 | Tony J. Soares | Sewer Inspector | Yes | PACP, LACP, MACP | Yes | Yes, MUTCD | Yes | Yes | ||

| 7 | Jason Atherton | Sewer Inspector | Yes | PACP, LACP, MACP | Yes | Yes, MUTCD | Yes | Yes | ||

| 8 | Sonny Quach | Sewer Inspector | Yes | PACP, LACP, MACP | Yes | Yes | Yes, MUTCD | Yes | Yes | |

| 9 | Joaquin ParraMartinez | Sewer Inspector | Yes | PACP, LACP, MACP | Yes | Yes, MUTCD | Yes | Yes | ||

| 10 | Rick Almondia | Sewer Inspector | No | PACP, LACP, MACP | Yes | Yes | Yes, MUTCD | Yes | Yes | |

| Staff Member | Title | Professional Engineer California | CWEA Certificati on | CCTV | Confined Space | Trench/ Excavation | Traffic Control | CPR/ First Aid/A ED | Water Sample Collection |

ELEMENT 5 – DESIGN AND PERFORMANCE STANDARDS

SWRCB Requirements:

a. Design and construction standards and specifications for the installation of new sanitary sewer systems, pump stations and other appurtenances; and for the rehabilitation and repair of existing sanitary sewer systems; and

b. Procedures and standards for inspecting and testing the installation of new sewers, pumps, and other appurtenances and for rehabilitation and repair projects.

RWQCB Requirements:

Each wastewater collection system agency shall identify procedures and standards for inspecting and testing the installation of new sewers, pump stations, and other appurtenances; and for rehabilitation and repair projects.

Design Guidelines

The District utilizes the Design Guidelines for Sanitary Sewer for establishing minimum standards for construction of public sanitary sewers. The District’s Standard Details are intended to aid consulting engineers, developers, and others doing work in the City on public sanitary sewer projects. The District Standard Details are as follows:

• Manhole

• Flushing Inlet

• Concrete Encasement

• Sewer Lateral and Main, open cut and trenchless technology

• Synthetic Rubber Wedged Insert Tee

• Banded Wye Installation

• Solvent Weld Wye Installation

• Backflow Prevention Device Installation

• Property Line Cleanout for Lateral Sewer

Sanitary Sewer Design Procedures

The current District Sanitary Sewer Design Procedures dated 2012 are being updated as needed. The Design Procedures have been followed by District staff for in-house and consultant designed projects. Additional design procedures include:

•Preliminary Engineering includes planning, scheduling, budgeting, requesting for services or information from utility companies, material testing, survey, hydraulic analysis, preliminary design, and environmental clearance applications such as exemption, negative declaration, and/or EIR.

• Initial Design and Plan Check Distribution for review to utility companies, impacted agencies and involved departments and divisions including material testing lab, survey, and City Public Works Departments.

• Final Design includes property acquisition, request for insurance specification, request for encroachment permits, construction quantities and cost estimates, preparation of final plans and specifications, final review and approval, and bid and award.

The procedures ensure the communication, coordination, and collaboration with the involved parties in the design review process.

The complete District Standard Details are available at the District’s office at 20863 Stevens Creek Boulevard, Suite 100, Cupertino, CA 95014 and on the District’s website in Adobe PDF format at https://burbanksanitary.org/standard_details.

Other Design Standards Used

When alternative techniques for pipeline rehabilitation are used on an existing system, the design must conform to ASTM and appropriate industry standards. Some of the potential techniques that may be considered for District rehabilitation are:

• Directional Drilling

• Pipe Bursting

The engineering analysis during the design phase must include factors such as:

• Pipe size, length, and depth

• Existing pipe condition

• Capacity requirement

• Access conditions

• Right of way requirements

• Soil condition and cover

• Groundwater conditions

• Project locations

• Traffic conditions

• Environmental impacts

Inspection Guidelines

The District has prepared sewer inspection guidelines for the following items:

• Lateral Maintenance Inspection

• Trunk Main Maintenance Inspection

• Final Inspection for Property Line Cleanout and CCTV

• Inspection Checklist for Sewer Lateral Capping

• Pre and Post Construction Checklist and Punch List

• Contract Change Orders

• Reporting and Documentation

• Miscellaneous and testing

Construction Management

The District’s construction management includes continuous onsite inspection. Inspections are performed during the progress of the work and at the completion of construction. All acceptance testing for gravity sewers is performed in the presence of the District sewer inspectors. The project will not be accepted until all results of the testing of sewers meet the requirements of the project plans and specification and/or the established standards. If the acceptance testing fails, the District will require the contractor to submit a repair plan and conduct the repair per the approved repair plan. Acceptance testing is performed again until the testing results meet the District’s requirement.

A full-time District sewer inspector is assigned to CIP projects. The inspector will follow the project until its acceptance. Inspectors are under the supervision of District Manager-Engineer and should report any discrepancy directly to the supervisor. All communications between the contractor and District Manager-Engineer should be through the project inspector.

The inspector will mark any changes to the design plan in his/her working plans. At the acceptance of the project, the inspector will provide the marked working plans to the engineer for the marking of the “record-drawings” by updating all changes from the original plan drawing.

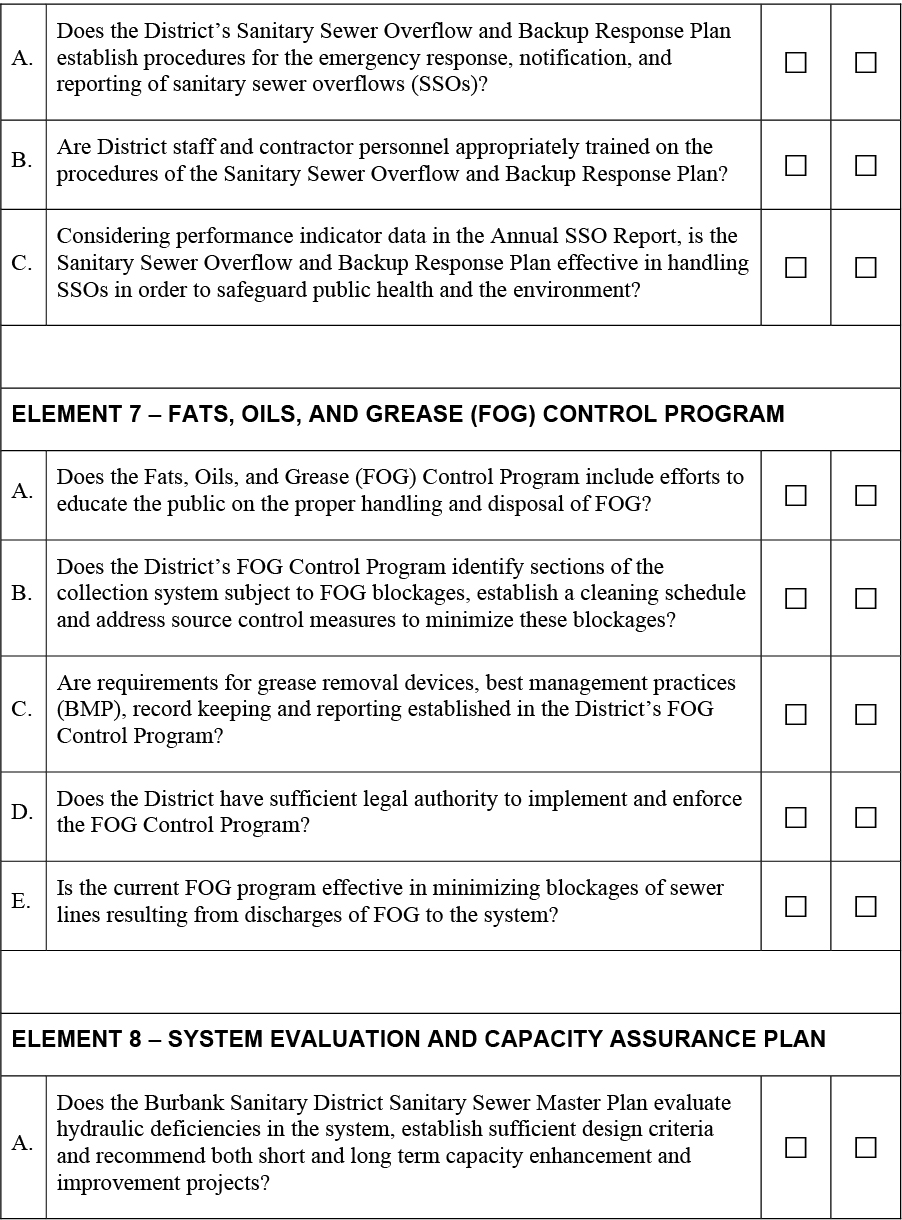

ELEMENT 6 – OVERFLOW AND EMERGENCY RESPONSE PLAN

SWRCB Requirements:

Each enrollee shall develop and implement an overflow emergency response plan that identifies measures to protect public health and the environment. At a minimum, this plan must include the following:

a. Proper notification procedures so that the primary responders and regulatory agencies are informed of all SSOs in a timely manner;

b. A program to ensure an appropriate response to all overflows;

c. Procedures to ensure prompt notification to appropriate regulatory agencies and other potentially affected entities (e.g., health agencies, Regional Water Boards, water suppliers, etc.) of all SSOs that potentially affect public health or reach the waters of the State in accordance with the MRP. All SSOs shall be reported in accordance with this MRP, the California Water Code, other State Law, and other applicable Regional Water Board WDRs or NPDES permit requirements. The Sewer System Management Plan (SSMP) should identify the officials who will receive immediate notification;

d. Procedures to ensure that appropriate staff and contractor personnel are aware of and follow the Emergency Response Plan and are appropriately trained;

e. Procedures to address emergency operations, such as traffic and crowd control and other necessary response activities; and

f. A program to ensure that all reasonable steps are taken to contain and prevent the discharge of untreated and partially treated wastewater to waters of the United States and to minimize or correct any adverse impact on the environment resulting from the SSOs, including such accelerated or additional monitoring as may be necessary to determine the nature and impact of the discharge.

RWQCB Requirements:

Each wastewater collection system agency shall develop an overflow emergency response plan with the following elements:

• Notification – Provide SSO notification procedures.

• Response – Develop and implement a plan to respond to SSOs.

• Reporting – Develop procedures to report and notify SSOs per SSO Monitoring and Reporting Program.

• Impact Mitigation – Develop steps to contain wastewater, to prevent overflows from reaching surface waters, and to minimize or correct any adverse impact from SSOs.

Sewer Overflow Response Plan

I. SSO Detection

A. Public Observation

B. District Personnel Observation

II. SSO Response and Procedure

A. Safety

B. Initial Response

C. Containment

D. Restore Flow

E. SSO Volume Estimation

F. Estimating of Recovery Volume of Spilled Sewage

G. Cleanup

H. Public Notification

I. Water Quality Sampling and Testing

III. Weekly SSO Meetings (

IV. Failure Analysis Investigation)

V. SSO Documentation and Reporting

A. SSO Categories

B. Internal SSO Reporting Procedures

C. External SSO Reporting Procedures

D. Internal SSO Documentation

E. External SSO Record Keeping Requirements

VI. Equipment

A. Closed Circuit Television (CCTV) Inspection Unit

B. Camera

C. GPS (Global Positioning System) Unit

D. Portable Generators, Portable Pumps, Piping and Hoses

VII. SSO Response Training

A. Initial and Annual Refresher Training

B. SSO Response Drills

C. SSO Training Record Keeping

D. Contractors Working on District Facilities

INTRODUCTION

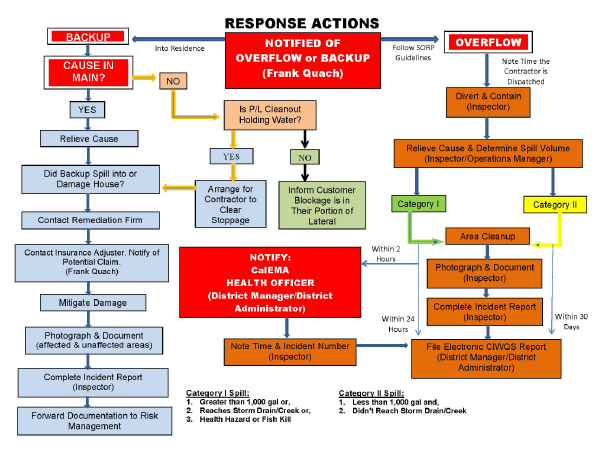

The purpose of this Overflow Emergency Response Plan is to provide Standard Operating Procedures (SOPs) for an orderly and effective response to Sanitary Sewer Overflows (SSOs). This plan provides courses of actions for SSO detection, response, containment, volume estimation, recovery, clean up, analysis, documentation, and reporting. The SSO response plan is described in this section and the response plan steps are shown on the flowchart Figure 7 on the next page.

I. SSO Detection

A. Public Observation

Public observation is the most common way that the District is notified of blockages and spills

Contact information for reporting sewer spills and backups are in the phone book and on the District’s website: https://burbanksanitary.org/. The public is instructed to call the District office at (408) 255-2137 between 8:00 am and 5:00 pm. County Communication at (408) 299-2507 dispatches sewage related calls to the first responder after hours, weekends, and holidays.

When a report of a sewer spill or backup is made, District staff receives the call, takes the information from the caller, and fills out the first section of a Service Request

The person who receives the call will verbally communicate the service request to the Sewer Inspector for follow up

B. District Personnel Observation

District personnel conduct periodic inspections of its sewer system facilities as part of their routine activities. Any problems noted with the sewer system facilities are reported to appropriate District personnel who in turn responds to emergency situations. Work orders are issued to correct nonemergency conditions.

II. SSO Response and Procedures

A. Safety

The first responder is responsible for following safety procedures at all times. Special safety precautions must be observed when performing sewer work to protect and restore public health, environment, and property from sewage spill events.

There may be times when District personnel responding to a sewer system event are not familiar with potential safety hazards for that particular sewer task. In such cases, it would be appropriate to take the time to identify hazards, discuss safety issues, consider the order of work, and check safety equipment before starting the job.

B. . Initial Response

All sanitary sewer system calls require a response to the reported location of the event to minimize or eliminate an overflow. The first responder must arrive at the site of the reported problem immediately and visually check for potential sewer stoppages or overflows.

Response Time – It is the goal of the District to respond to a SSO within 30 minutes of the first call during regular business hours (Monday thru Friday between 8:00 am and 5:00 pm), and within 60 minutes after hours, during weekends, and on holidays.

First Responder’s (First Person at SSO site) Role is to:

• Identify and clearly assess the affected area and extent of spill and note arrival time at spill site.

• Establish perimeters and control zones with traffic cones, barricades, vehicles, or terrain.

Document conditions upon arrival with photographs.

• Promptly notify the Authorized Representative in the event of a Category 1 SSO or when the spill appears to be large, in a sensitive area, or there is doubt regarding the extent, impact, or how to proceed, and request additional resources (e.g. people, equipment, etc.)

• Contain and control the sewage discharged to the maximum extent possible.

• Make every effort to prevent the discharge of sewage into waterways.

• Restore the flow as soon as practicable and contact the caller for additional information. Depending on the situation, utilize the combination sewer cleaning truck and/or spill response vehicle.

• Return the spilled sewage to the sewer system

• Restore the area to its original condition (or as close as possible)

Note: Containment is a higher priority than restoring flow, but this depends on the

circumstances.

• If the problem is in a private sewer lateral and the flow has entered public right of way, then the first responder should:

o Request the resident to cease activities that are causing continuation of the sewer spill (e.g., flushing toilets, washing laundry, etc.)

o Request the resident to call a plumber to correct the problem with their lateral and stand by until the plumber arrives.

o Contain any spilled sewage that has entered the public right of way and return it to the sanitary sewer system.

C. Containment

Decide whether to proceed with clearing the blockage to restore the flow or to initiate containment measures. The guidance for this decision is:

• Small Spills (less than 50 gallons) – proceed with clearing the blockage.

• Moderate spill where containment is anticipated to be simple (greater than 50 gallons to 999 gallons) – proceed with containment measures.

• Large spills where containment is anticipated to be difficult (greater than 1000 gallons) – proceed with clearing the blockage, however, call for additional assistance after 15 minutes if unable to clear the blockage and implement containment measures.

The first responder should also attempt to contain as much of the spilled sewage using the following steps:

• Determine the immediate destination of the overflowing sewage.

• Plug storm drains using air plugs, sandbags, and/or plastic mats to contain the spill, whenever appropriate. If spilled sewage has made contact with the storm drainage system, attempt to contain the spilled sewage by plugging downstream storm drain facilities.

• Contain/direct the spilled sewage using dike/dam or sandbags

• Pump around the blockage/pipe failure.

D. Restore Flow

Attempt to remove the blockage from the system and observe the flows to ensure that the blockage does not recur downstream

If blockage cannot be cleared within a reasonable time (15 minutes), or the sewer facility requires construction repairs to restore flow, then initiate containment and/or bypass pumping. If assistance is required, immediately contact the Authorized Representative, other employees, contractors, and equipment suppliers.

E. SSO Volume Estimation

A variety of approaches exist for estimating the volume of a sanitary sewer spill. It should be noted that the person preparing the estimate should use the method most appropriate to the sewer overflow in question and use the best information available. Below are three commonly used methods:

1. Measured Volume – The volume of most spills that have been contained can be estimated using this method. The shape, dimensions, and the depth of the contained wastewater are needed. The shape and dimensions are used to calculate the area of the spills and the depth is used to calculate the volume.

Step 1 Sketch the shape of the contained sewage.

Step 2 Measure or pace off the dimensions.

Step 3 Measure the depth at several locations and select an average.

Step 4 Convert the dimensions, including depth, to feet.

Step 5 Calculate the area in square feet using the following formulas:

Rectangle: Area = length (feet) x width (feet)

Circle: Area = diameter (feet) x diameter (feet) x 0.785

Triangle: Area = base (feet) x height (feet) x 0.5

Step 6 Multiply the area (square feet) times the depth (in feet) to obtain the volume in cubic feet.

Step 7 Multiply the volume in cubic feet by 7.5 to convert to gallons

2. Duration and Flow Rate – Calculating the volume of spills, where it is difficult or impossible to measure the area and depth, requires a different approach. In this method, separate estimates are made of the duration of the spill and the flow rate. The methods of estimating duration and flow rate are:

Duration: The duration is the elapsed time from the time the spill started to the time that the flow was restored. Duration time for a SSO does not include the time required to perform cleaning efforts.

Flow Rate: The flow rate is the average flow that left the sewage system during the time of the spill. The San Diego Manhole Flow Rate Chart is used to estimate the manhole overflow rate. Photographs showing the actual measurement should be taken in documenting the basis for the flow rate estimate.

SSO Start Time: The start time is sometime difficult to establish. Below are suggestions for determining spill start times:

• Nearby Witnesses: Witnesses can be used to establish start time. Contact and interview the reporting party, nearby residents, business owners or any witnesses that may have observed the incident. Inquire as to their observations. Spills that occur in public right of are usually observed and reported promptly. Spills that occur out of the public view can go on longer. Sometimes, observations like odors or sounds (e.g. water running in a normally dry creek bed) can be used to estimate the start time.

• Site Conditions: Conditions at the spill site change over time. Initially there will be limited deposits of toilet paper and other sewage solids. After a few days to a week, the sewage solids form a light-colored residue. After a few weeks to a month, the sewage solids turn dark. The quantity of toilet paper and other materials of sewage origin increase over time. These observations can be used to estimate the start time in the absence of information. Taking photographs to document the observations can be helpful if questions arise later in the process.

• Accounting for Flow Variations: It is important to remember that spills may not be continuous. Blockages are not usually complete (some flow continues). In this case the spill would occur during the peak flow periods (typically 10:00 to 12:00 and 13:00 to 16:00 each day). Spills that occur due to peak flows in excess of capacity will occur only during and for a short period after heavy rainfall.

• Spill Volume/Flow Rate: Start time can be calculated using estimated flow rate and estimated spill volume. District personnel will use the San Diego Manhole Flow Rate Chart to estimate the flow rate and to estimate the spill volume using approved methodology (please see method 2 calculation above). The start time then is calculated by using both the estimated flow rate and the estimated spill volume.

SSO Stop Time: The stop time is usually much easier to establish. The stop time is determined when field crews confirm that the SSO has stopped. This typically is the time when the blockage has been removed

Spill Volume Calculation Using Flow Rate: Once duration and flow rate have been estimated the volume of the spill is the product of the duration in hours or days and the flow rate in gallons per hour or gallons per day

Example: Spill Start Time: 14:00

Spill Duration: 3 Hours

Flow Rate: 3.3 gallons per minute

3.3 gallons per minute x 60 minutes per hour x 3 hours = 594 gallons

F. Estimating Recovery Volume of Spilled Sewage

The following methods can be used, depending on the circumstances, for estimating recovered sewage volume:

1. Two Truck Sewage Recovery Method: The sewage recovery and cleanup effort often requires fresh de-chlorinated water to clean the affected area or storm pipe lines. The collected liquid in the tank would not represent the actual spill sewage volume if water is introduced for cleanup. By using this method, District inspectors will require the contractor to use two Vactor trucks, one with an empty tank at a downstream storm drain manhole or inlet and one with filled fresh de-chlorinated water at an upstream storm drain manhole or inlet where fresh de-chlorinated water is introduced. The total recovered volume will include cleanup water and sewage which can be used to calculate the sewage spill volume. The total amount of the collected water less the cleanup water introduced would provide the actual sewage spill/recovered.

2. Pipe Volume Calculation: Using this method, before vacuuming the sewage from the storm pipe line into a tank, the contractor will block the storm pipe line downstream, video the storm main and measure the level of liquid standing in the pipe. By knowing the pipe size, level of liquid in the pipe, and the length of pipe filled, the spill sewage volume can be calculated.

A. Water Quality Monitoring

In accordance with subsection D.7(v) of the SSS WDRs, water quality monitoring program to assess impacts from SSO’s to surface waters in which 50,000 gallons or greater are spilled into surface water shall include the following:

1. Protocols for water quality monitoring shall include, at minimum, visual inspection, determination of volume of total spills and estimated volume entering the surface water, and/or spill travel time in the surface water where monitoring may not be possible due to safety concerns, access restrictions, etc.

2. Within 48 hours, water quality sampling for, at a minimum, the following constituents:

a. Ammonia

b. Appropriate bacterial indicators per the applicable Basin Plan water quality objectives, which may include total and fecal coliform, enterococcus, and e-coli.

3. Water quality analysis shall be performed by an accredited or certified laboratory and instruments/devices used to implement the SSO Water Quality Monitoring Program shall be properly maintained and calibrated, as necessary, to ensure their continued accuracy

G. Water Quality Sampling and Testing

Water quality sampling and testing is required when 50,000 gallons or greater are spilled to surface water to determine the extent and impact of the SSO. Water quality samples will be taken whenever adverse impacts to surface waters (i.e. fish kill) is visually observed, the sampling can be safely obtained from the impacted water body, and the act of sampling does not prevent the District from completing the necessary SSO response actions.

• Conduct water quality sampling within 48 hours after initial SSO notification for Category 1 SSOs in which 50,000 gallons or greater are spilled to surface waters.

Water quality results are required to be uploaded into CIWQS in which 50,000 gallons or greater are spilled to surface waters.

• The following steps should be taken to collect water quality samples:

a) Samples should be collected from upstream of the spill, from the spill area, and downstream of the spill (e.g., creeks).

b) Samples should be collected near the point of entry of the spilled sewage and every 100 feet along the shore of stationary water bodies.

• The City of San Jose Environmental Services Department laboratory will analyze the sample to determine the nature and extent of impact from the discharge. Additional sample will be taken to determine if posting of warning signs should be discontinued. The basic analyses should include pH, temperature, total coliform, fecal coliform, biochemical oxygen demand (BOD), dissolved oxygen, and ammonia nitrogen.